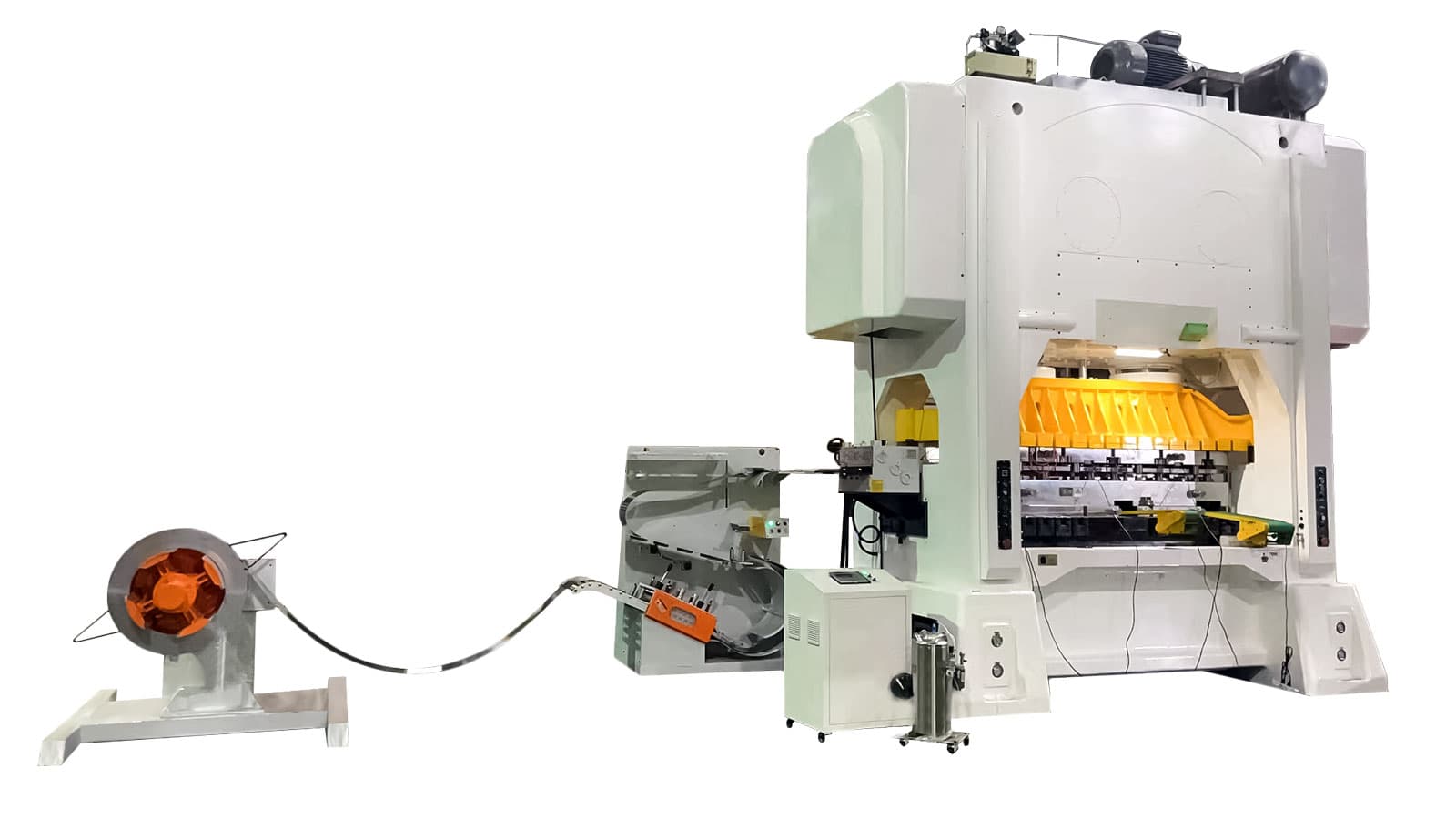

METAL STAMPING PRESS MACHINE

Precision metal stamping press with a capacity of 60-500 tons RPH series

Stamping Machine Features

- Frame Structure: High-alloy steel casting, designed through computer analysis to create the most suitable frame.

- After eliminating internal stresses, this process enhances precision and ensures the rack's indispensable high rigidity, thereby achieving low vibration technology to improve mold longevity.

- We prioritize high-precision stability and reliability.

Standard Configuration

- Electric die height adiusting equipment.

- Stamp height indication accuracy 0.01 mm.

- Slow positioning device (jog mode).

- 30 sets memory for die setting data.

- Three automatic stacking control groups.

- 2 sets of mis-feed detecting receptcle.

- Two way rotation main motor control.

- Hydraulic clamping unit for die height adjusting.

- Lubricant cooling device.

- Integrated brake-clutch (Italy).

- Independent electric control box.

- Tool box.

- Work light.

- Inverter control for main motor.

Optional Configuration

- Precision bottom dead center detector.

- Hydraulic die clamping device.

- Hydraulic die lifting device.

- Hi-speed gear change feeder.

- Double head un-coiler.

- Leveling and unloading machine.

- Anti-vibration mounts.

- F-3SC stamping controller.

- Two side sound proof safety door.

Technical parameters

| Model | Unit | RPH-60 | RPH-80 | RPH-125 | RPH-150 | RPH-200 | RPH-220 | RPH-300 | RPH-350 | RPH-400 | RPH-550 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | ton | 60 | 80 | 125 | 150 | 200 | 220 | 300 | 350 | 400 | 550 |

| Stroke | mm | 30 | 30-50 | 40 | |||||||

| Strokes per minute | s.p.m | 200-800 | 200-700 | 150-700 | 150-600 | 150-400 | 150-350 | 80-250 | |||

| Bolster Area | mm | 950 × 650 | 1100 × 750 | 1200 × 850 | 1400 × 850 | 1800 × 950 | 1900 × 1000 | 2400 × 1000 | 2800 × 1200 | 3300 × 1300 | |

| Bolster Hole | mm | 700 × 125 | 800 × 150 | 1000 × 200 | 1300 × 250 | 1400 × 300 | 2200 × 300 | 2200 × 400 | 3300 × 500 | ||

| Slide Dimension | mm | 950 × 420 | 1100 × 500 | 1200 × 600 | 1400 × 600 | 1800 × 700 | 1900 × 750 | 2400 × 900 | 2800 × 1100 | 3300 × 1200 | |

| Die Height Adjustment | mm | 300-350 | 330-380 | 360-410 | 370-420 | 400-450 | 420-480 | 500-550 | |||

| Adjustment Motor | kW | 0.4 | 0.75 | 1.5 | 2.2 | 3.7 | 5.2 | ||||

| Linear Height | mm | 160 | 175±50 | 195±50 | 200±50 | 210±50 | 220±50 | 240±50 | |||

| Main Motor | kW | 10 | 22 | 37 | 45 | 55 | 75 | 90 | |||

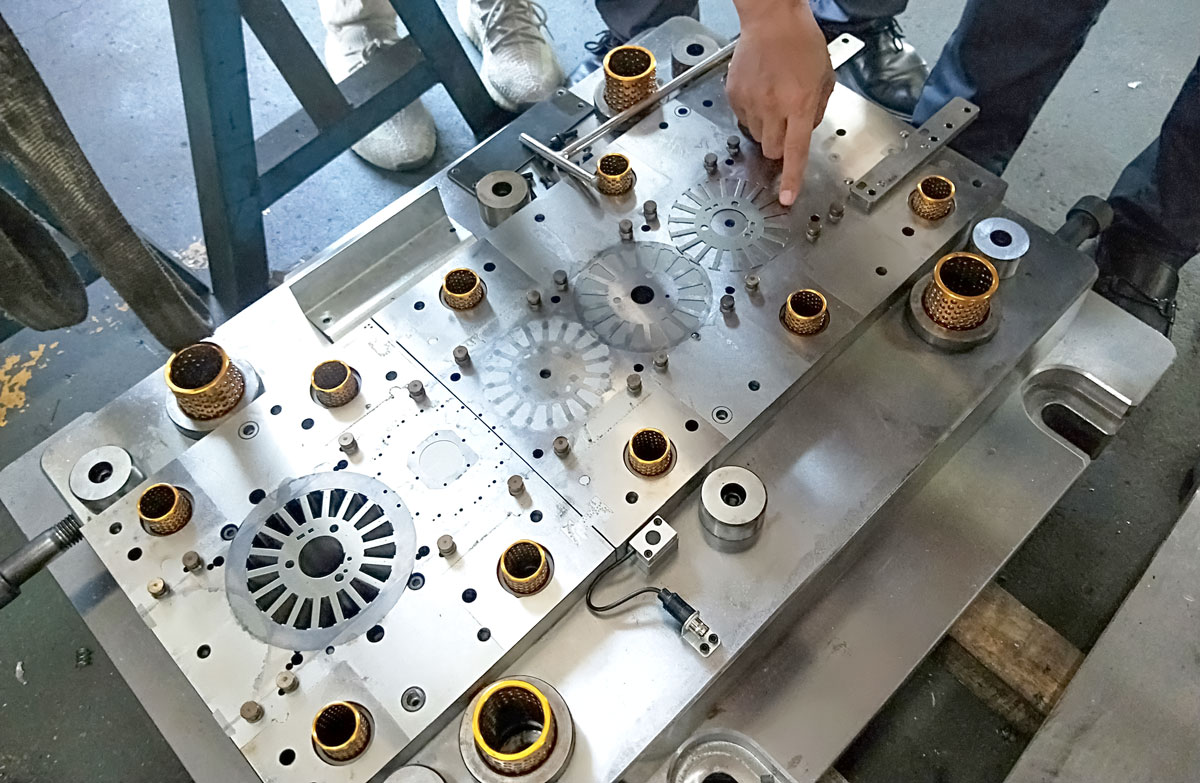

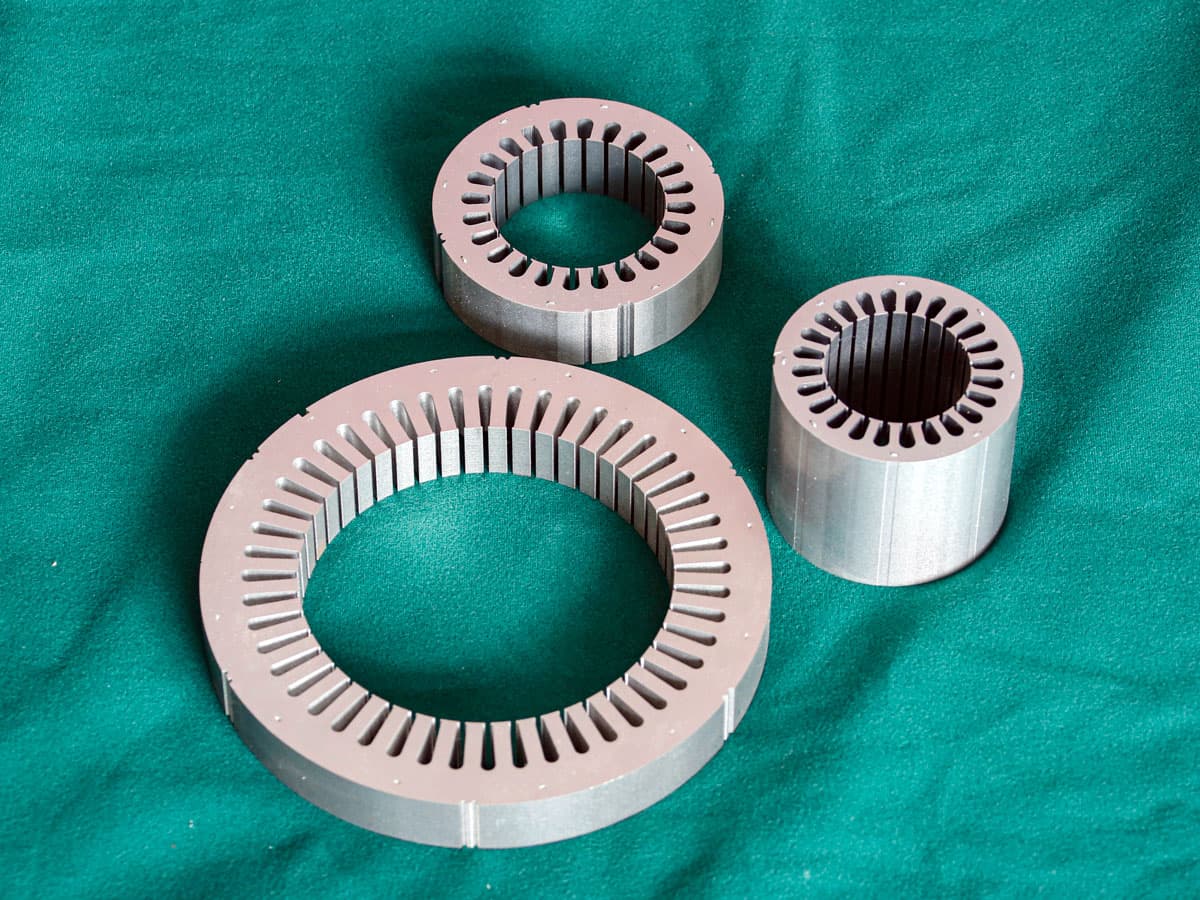

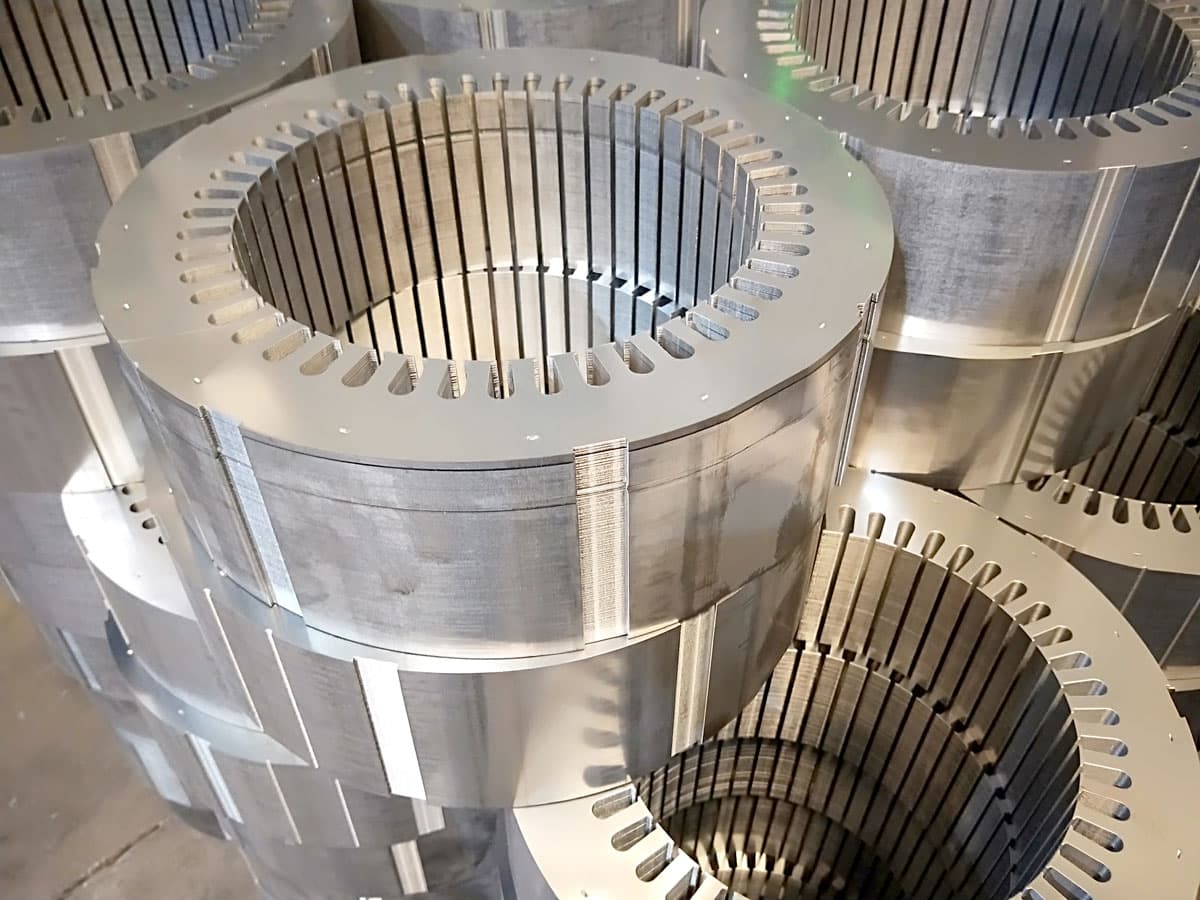

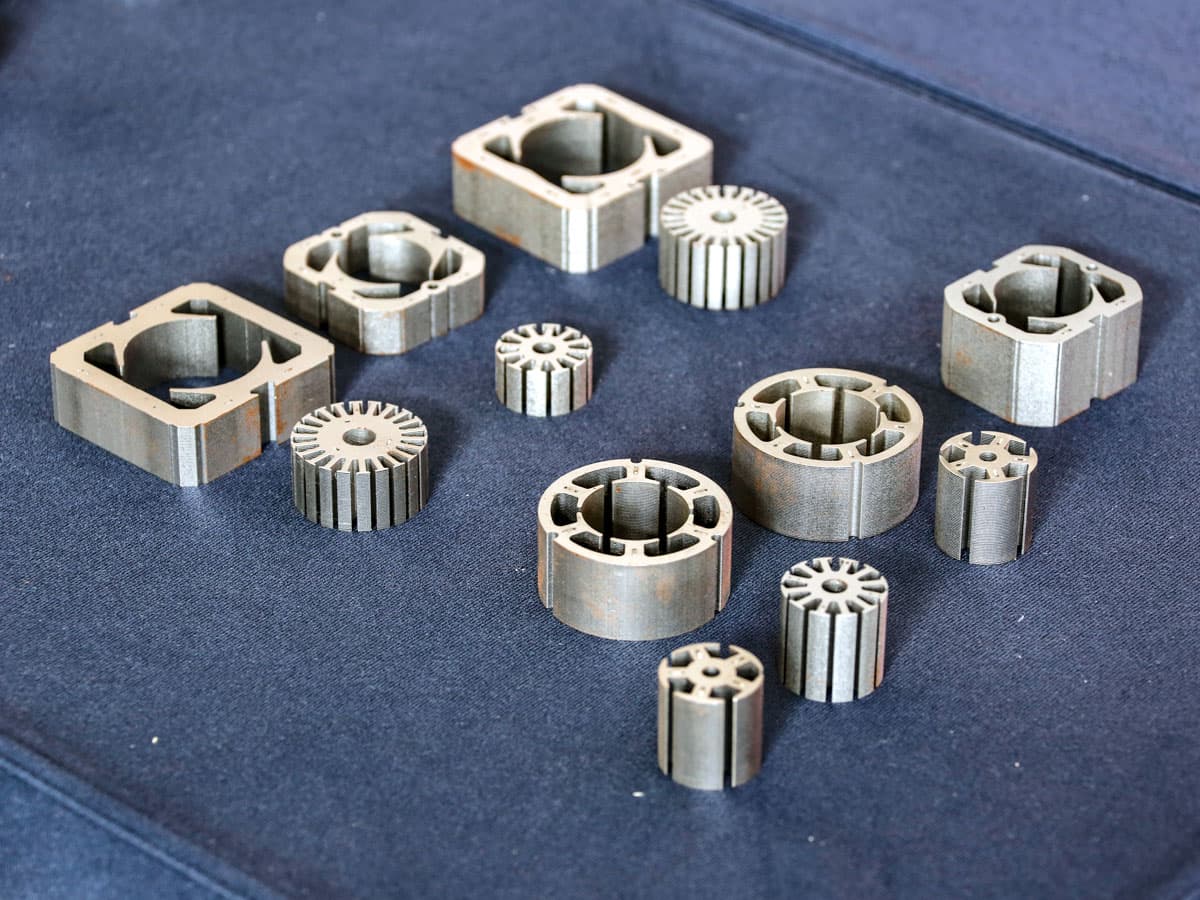

Samples of stamped products

Stamping of stators and rotors of electric motors on the RPH-350 press

R2 Series 400-1600 Ton Double Point Straight Column Punching Press

Punch Press Features

- The clutch brake utilizes a low-inertia pneumatic clutch brake system, controlled by a dual safety valve.

- The mold height can be adjusted using a digital display.

- Electrical control is achieved through a PLC dual-loop system.

- High-quality brand-name products are employed for hydraulic, pneumatic, and electrical control components.

- Lubrication is achieved through a thin oil circulating system and concentrated oil clearance lubrication, featuring high and low-level detection, high-pressure monitoring, timing, fixed-point, and precise quantitative lubrication. The system includes oil pressure and oil level monitoring, fault detection, and various action sequences.

- The slide block is equipped with a hydraulic pressure overload protection device.

- Key components have undergone finite element analysis for enhanced performance and durability.

- Optional features include an air cushion, specialized vibration isolator, quick die-changing device, photoelectric protection system, and rigid materials, among others.

Standard Configuration

- Hydraulic Overload Protection Device.

- Automatic Lubricating Device.

- Electric Slide Adjusting Device.

- Electric Die Height Indicator.

- Slide and Die Balancing Device.

- Electronic Cam Control Display.

- Lifting Brake Performance Monitoring Device.

- Static SPM Display Function.

- Air Source Plug Base.

- Air Blowing Device.

- Over Run Protection Device.

- The Frequency Control Motor.

- Misfeed Detecting Device.

- Motor fed-rev Device.

- Stroke Counter.

- Preset Counter.

- Power Socket.

- Independent Control Box.

- Movable T-beam.

- Base Plate and Bolts.

- Maintenance Tool Box.

- Operation Manual.

Optional Configuration

- Pneumatic Die Cushion.

- Photoelectric Safety Device.

- Slide Knock-out Device.

- Die Lamp.

- B.D.C. Detector.

- Foot Pedal Switch.

- Flywheel brake device.

- Safety Block Bolt.

- Moving Bolster.

- Quick Die Change System.

- Automatic Feeding System.

- Anti-vibration Pads.

Technical parameters

| Model | Unit | R2-400 | R2-500 | R2-630 | R2-800 | R2-1000 | R2-1250 | R2-1600 | |

|---|---|---|---|---|---|---|---|---|---|

| Nominal Pressure | kN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 | |

| Nominal Pressure Stroke | mm | 13 | |||||||

| Slide Stroke | mm | 400 | 500 | 600 | |||||

| Strokes per minute | s.p.m | 12-18 | 10-16 | ||||||

| Max. Die Height | mm | 800 | 1000 | 1100 | |||||

| Die Height Adjustment | mm | 350 | 500 | 600 | |||||

| Distance between slide rails | mm | 2870 | 3160 | 3670 | 4060 | 4070 | 4080 | 4580 | |

| Bolster Area | L | mm | 1600 | 1800 | |||||

| W | mm | 2800 | 3000 | 3600 | 4000 | 4500 | |||

| H | mm | 180 | 220 | 250 | 280 | 300 | 340 | ||

| Slide Dimension | L | mm | 1600 | 1800 | |||||

| W | mm | 2800 | 3000 | 3600 | 4000 | 4500 | |||

| Air Cushion | Pressing force / Return force | kN | 600 | 800 | 1000 | 1250 | 1500 | ||

| Stroke | mm | 200 | 220 | 240 | 250 | ||||

| Knocking out of Slide (optional) | Stroke | mm | 150 | ||||||

| Main Motor Power | kW | 75 | 90 | 132 | 160 | 220 | |||

| Overall Dimension | L | mm | 4350 | 4900 | 4080 | 6870 | 7290 | 7500 | 8450 |

| W | mm | 5180 | 5770 | 5420 | 5530 | 5600 | 6000 | 6320 | |

| H | mm | 6980 | 7900 | 7980 | 8860 | 9600 | 10600 | 11000 | |

Samples of stamped products

Progressive stamping press die