SPRING FORMING MACHINES

3AXIS CNC SPRING FORMING MACHINE

CNC spring forming machine main features

- The Spring Forming Machine is equipped with a computer-controlled system made in Taiwan and a servomotor from Japan.

- A high-precision inspection tracer device is installed; it will stop working automatically when defective product is detected.

- The parameters (major diameter, angle, etc.) can be modified at any time according to the working status displayed on the fluorescence screen.

- The Spring Forming Equipment is suitable for producing double torsion spring, straight spring, pagoda-shaped compression spring, rectangle spring, swirl spring, special-shaped spring and etc.

Technical Parameters

| Model | RG-625-CNC | RG-635-CNC | RG-650-CNC |

|---|---|---|---|

| Wire diameter (mm) | Ø0.3 ~ Ø2.5 | Ø1.5 ~ Ø3.5 | Ø2 ~ Ø5 |

| Max outside diameter (mm) | Ø50 | Ø60 | Ø100 |

| Instrution value of wire feed (mm) | ±0.01 ~ ±9999.99 | ±0.01 ~ ±9999.99 | ±0.01 ~ ±9999.99 |

| Instrution value of cam | ±0.1° ~ ±359.9° | ±0.1° ~ ±359.9° | ±0.1° ~ ±359.9° |

| Savable system | 99 Groups | 99 Groups | 99 Groups |

| Motor power (kw) | axis X-Y 2.7 kw axis Z 1 kw | axis X-Y 5.5 kw axis Z 1 kw | axis X-Y 11 kw axis Z 1 kw |

| Machine weight (kg) | 800 | 1500 | 3500 |

| Voltage | Three Phase AC380V 50HZ | Three Phase AC380V 50HZ | Three Phase AC380V 50HZ |

| Machine dimension (LxWxH) | 1630 x 880 x 1980 mm | 1850x1060 x 2150 mm | 2000 x 1080 x 2250 mm |

Equipment operation video

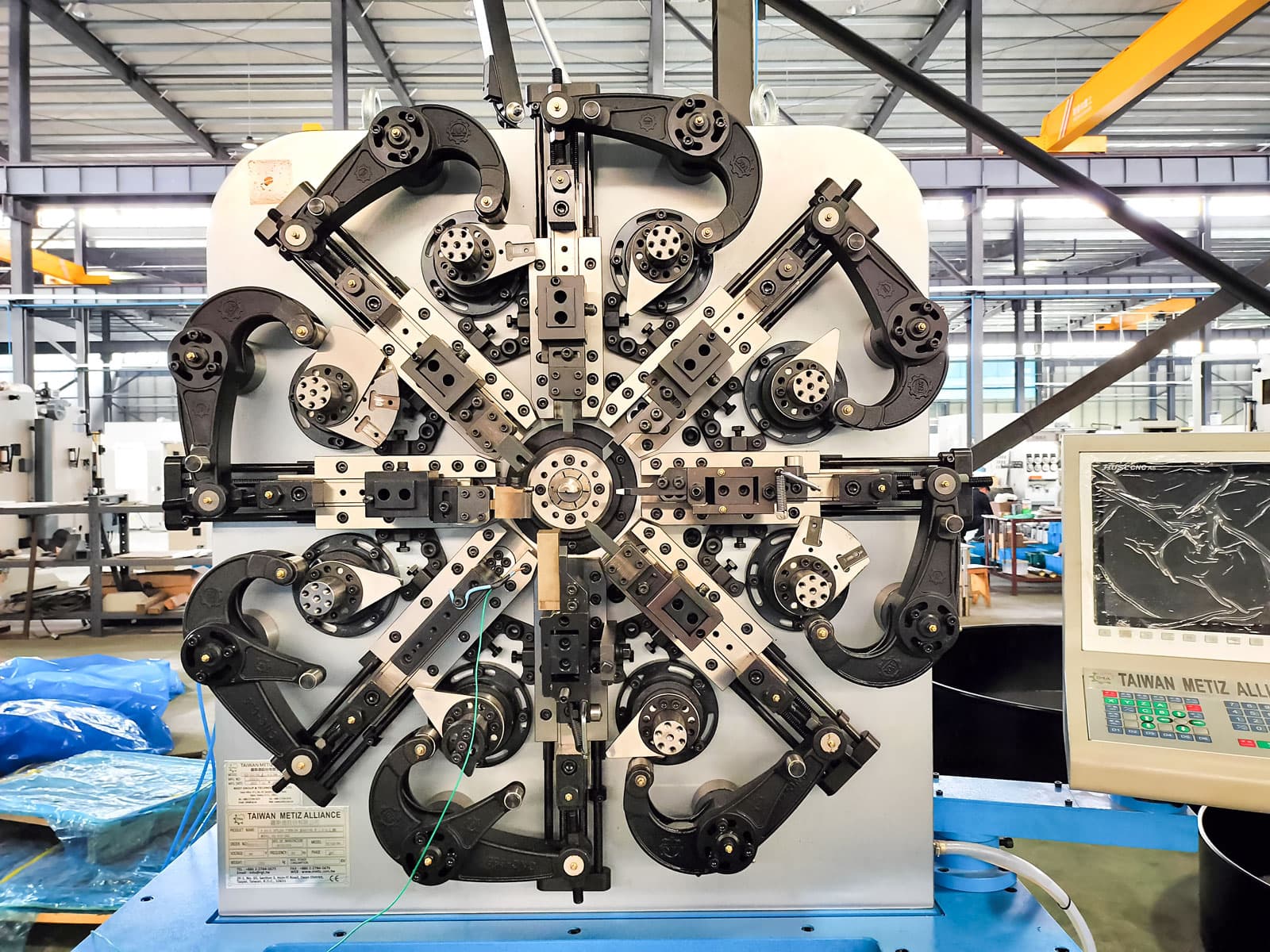

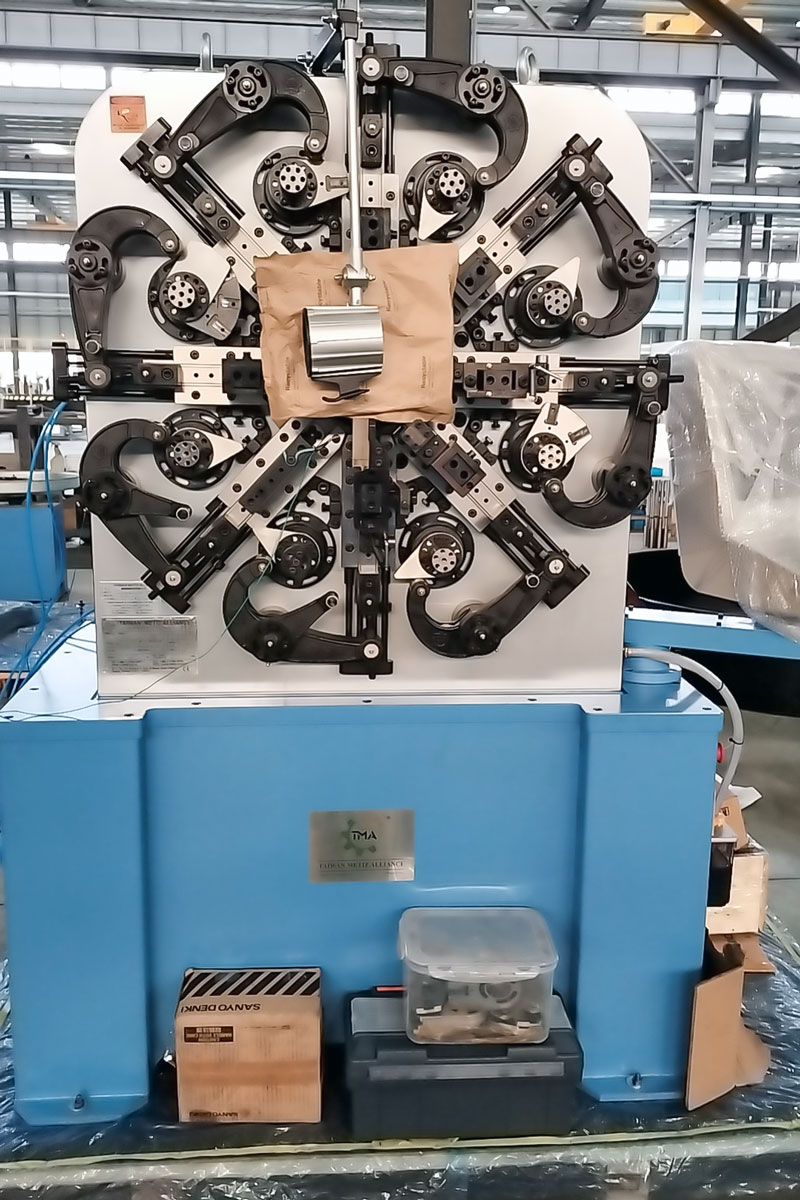

12AXIS CNC SPRING CAMLESS MACHINE

Main Features of CNC Spring Camless Machine

- This machine has a Camless design; it forms springs with high speed, accuracy and good stability.

- Camless Spring Forming Machine is equipped with a computer control system from Taiwan and a servomotor imported from Japan.

- Wire feed comes with a rotary wire function, so it is easy to adjust.

- Computer interface is available in Chinese and English, which makes the operation easy.

- It is suitable for producing double torsional spring, straight spring, pagoda-shaped compression spring, rectangle spring, swirl spring and other different spring and special - shape spring etc.

Technical Specifications of CNC Spring Camless Machine

| Model | RG-1225-CNC | RG-1240-CNC | RG-1260-CNC | RG-1280-CNC |

|---|---|---|---|---|

| Wire Diameter (carbon steel wire) | Ø0.3 - Ø2.5 mm | Ø1.5 - Ø4 mm | Ø2 - Ø6 mm | Ø3 - Ø8 mm |

| Total Power | 14.8 kw | 26.2 kw | 54.5 kw | 71.4 kw |

| Number of Axes | 12 | |||

| Number of Wire Feed Axes | 2 Pairs | 3 Pairs | 4 Pairs | |

| Wire Feed Servo Motor | 2.7 kw | 5.5 kw | 11 kw | 15 kw |

| Rotary Wire Servo Motor | 3.8 kw | 2.7 kw | 4.5 kw | 15 kw |

| Blade of Slider Servo Motor | 1×8 kw | 2×8 kw | 4.5×8 kw | 4.5×8 kw |

| Rotary Mandrel Servo Motor | 1 kw | 1.5 kw | 2.7 kw | |

| Curved Shaft Servo Motor | 0.4 kw | 1 kw | 1.5 kw | 2.7 kw |

| Machine dimension (LxWxH) | 1700 × 1600 × 1685 mm | 2100 × 1900 × 2000 mm | 2700 × 2000 × 2250 mm | 3500 × 2400 × 2500 mm |

| Machine Weight | 1500 kg | 4000 kg | 7000 kg | 8000 kg |

| Voltage | Three Phase AC380V 50HZ | |||

CNC SPRING COILING MACHINE

CNC spring coiling machines is equipped with a number 3, 4, 6 axis, which allows easily produce compression springs, coil springs in two or three successive steps. Changing the parameters of the equipment, such as changing the diameter of manufactured products can be carried out using the control panel interface. The length and speed of the wire feed is controlled and regulated by a computer program. The equipment stops automatically when the failure or absence of wire.

SPECIFICATIONS

| Model | RG-208-CNC | RG-212-CNC | RG-230-CNC | RG-238-CNC | RG-265-CNC | RG-280-CNC |

|---|---|---|---|---|---|---|

| Wire diameter | 0.13-0.8 mm | 0.3-1.2 mm | 0.8-3.0 mm | 1.6-3.8 mm | 2.6-6.5 mm | 3.0-8.0 mm |

| Max. Wire feed speed | 90 m / min. | 90 m / min. | 110 m / min. | 110 m / min. | 70 m / min. | 70 m / min. |

| Max. Wire length | no restrictions | no restrictions | no restrictions | no restrictions | no restrictions | no restrictions |

| Max. Spring outer diameter (* see Note) | 20 mm | 20 mm | 50 mm | 60 mm | 100 mm | 100 mm |

| Performance | 600 pcs / min. | 500 pcs / min. | 145 pcs / min. | 120 pcs / min. | 60 pcs / min. | 60 pcs / min. |

| Winding direction | right / left | right / left | right / left | right / left | right / left | right / left |

| Power | 1.75 kW | 2.75 kW | 6.5 kW | 8.4 kW | 16.5 kW | 22.5 kW |

| Hydraulic Press | - | - | - | - | - | 3 hp |

| Engine power for the coolant | - | - | - | - | - | 1/4 hp |

| Model unwinding device for wire | RG-70E | RG-70E | RG-600E | RG-1000E | RG-1500E | RG-1500E |

| Dimensions of equipment | 72 × 101 × 138 cm | 72 × 108 × 138 cm | 140 × 136 × 170 cm | 203 × 130 × 200 cm | 164 × 228 × 212 cm | 164 × 228 × 212 cm |

| Weight of equipment | 340 kg | 395 kg | 1350 kg | 1660 kg | 3600 kg | 3580 kg |

| Dimensions of equipment in packaging | 85 × 146 × 156 cm | 85 × 140 × 156 cm | 155 × 150 × 91 cm | 218 × 145 × 224 cm | 245 × 182 × 242 cm | 245 × 182 × 242 cm |

| Weight of Equipment in Packaging | 550 kg | 605 kg | 1600 kg | 2010 kg | 4080 kg | 4060 kg |

COMPRESSION AND COIL SPRINGS MAKING CNCMACHINE

Hardware Specifications

| Model | RG-2120-CNC | RG-412-CNC | RG-430-CNC | RG-438-CNC | RG-465-CNC | RG-480-CNC | RG-4120-CNC |

|---|---|---|---|---|---|---|---|

| Wire diameter | 5.0-12.0 mm | 0.3-1.2 mm | 0.8-3.0 mm | 1.6-3.8 mm | 2.6-6.5 mm | 3.0-8.0 mm | 5-12 mm |

| Max. Wire feed speed | 60 m / min. | 90 m / min. | 110 m / min. | 110 m / min. | 70 m / min. | 70 m / min. | 60 m / min. |

| Max. Wire length | no restrictions | no restrictions | no restrictions | no restrictions | no restrictions | no restrictions | no restrictions |

| Max. Spring outer diameter (min. ext. diameter spring wire diameter must exceed three times) | 150 mm | 20 mm | 50 mm | 60 mm | 100 mm | 100 mm | 150 mm |

| Performance | 35 pcs / min. | 500 pcs / min. | 120 pcs / min. | 120 pcs / min. | 50 pcs / min. | 50 pcs / min. | 40 pcs / min. |

| Winding direction | right / left | right / left | right / left | right / left | right / left | right / left | right / left |

| Power | 37 kW | 3.9 kW | 8.25 kW | 10.7 kW | 19.7 kW | 26.9 kW | 45.5 kW |

| Hydraulic Press | 5 hp | - | - | - | - | 3 hp | 5 hp |

| Engine power for the coolant | 1/4 hp | - | - | - | - | 1/4 hp | 1.4 hp |

| Model unwinding device for wire | RG-1500E | RG-70E | RG-70E | RG-1000E | RG-1500E | RG-1500E | RG-1500E |

| Dimensions of equipment | 343 × 215 × 245 cm | 72 × 108 × 138 cm | 140 × 136 × 170 cm | 203 × 130 × 200 cm | 164 × 228 × 212 cm | 164 × 228 × 212 cm | 343 × 215 × 245 cm |

| Weight of equipment | 12400 kg | 425 kg | 1480 kg | 1700 kg | 3655 kg | 3670 kg | 12800 kg |

| Dimensions of equipment in packaging | 376 × 233 × 273 cm | 85 × 140 × 156 cm | 155 × 150 × 91 cm | 218 × 145 × 224 cm | 245 × 182 × 242 cm | 245 × 182 × 242 cm | 376 × 233 × 273 cm |

| Weight of Equipment in Packaging | 13400 kg | 635 kg | 1710 kg | 2050 kg | 4135 kg | 4150 kg | 13800 kg |

COMPRESSION AND COIL SPRINGS MAKING MACHINE

The equipment is suitable for the production of various types of springs: for machinery, equipment, toys, appliances, furniture, stationery, pens, umbrellas, motorcycles, bicycles, tools and so on.

Source material: spring wire, wire for fortepiano, stainless steel wire, steel wire, galvanized wire, copper wire, etc.

SPECIFICATIONS

| Model | RG-08 | RG-15 | RG-45 |

|---|---|---|---|

| Wire diameter | 0.13-0.8 mm | 0.3-1.6 mm | 2.0-4.5 mm |

| Wire length | Ø0.13-0.5 mm= 1080 mm Ø0.6-0.8 mm= 500 mm | Ø1.1-1.6 mm= 860 mm Ø0.7-1.0 mm= 1515 mm Ø0.3-0.6 mm= 2600 mm | Ø4.5-Ø470 mm Ø4.0-Ø950 mm Ø3.0-Ø1680 mm Ø2.3-Ø3200 mm |

| Max. Spring outer diameter (min. ext. diameter spring wire diameter must exceed three times) | 20 mm | 30 mm (30 mm (for the wire Ø1.1-1.6 mm inner diameter of the spring should six times exceed the wire diameter) | 55 mm |

| Performance | 45-230 pcs / min. | 60 Hz: 28,52,82,118, 4 steps 50 Hz: 23,43,68,98, 4 steps | 60 Hz: 4,6,10,14,19,30,48,69 50 Hz: 3,5,8,12,16,25,40,58 |

| Winding direction | clockwise/counter-clockwise | clockwise/counter-clockwise | clockwise/counter-clockwise |

| Basic engine | 1 hp | 1 hp | 5 hp, 1/4 hp, 3 phase |

| Model unwinding device for wire | RG-70E | RG-6 | RG-6 |

| Dimensions of equipment | 70 × 70 × 167 cm | 77 × 92 × 135 cm | 150 × 142 × 172 cm |

| Weight of equipment | 355 kg | 570 kg | 2000 kg |

| Dimensions of equipment in packaging | 86 × 165 × 191 cm | 161 × 92 × 162 cm | 164 × 155 × 206 cm |

| Weight of Equipment in Packaging | 480 kg | 680 kg | 2300 kg |

COMPRESSION SPRING MAKING MACHINE

SPECIFICATIONS

| Model | RG-1350-G | RG-2870-G |

|---|---|---|

| Wire diameter | Ø1.0-Ø3.0 | Ø2-Ø8 mm |

| Spring length | 10-150 mm | 18-300 mm |

| Spring outer diameter | Ø6-Ø50 mm | Ø10-Ø70 mm |

| Engine power | 5 hp × 2, 1 hp × 1 | 5 hp × 4, 1 hp × 1 |

| The size of the grinding mechanism | 400 mm × 2 pcs. | 400 mm × 4 pcs. |

| Dimensions of equipment | 150 × 102 × 210 cm | 180 × 142 × 230 cm |

| Dimensions of equipment in packaging | 168 × 117 × 220 cm | 198 × 157 × 226 cm |

| Weight of equipment | 2000 kg | 3150 kg |

| Weight of Equipment in Packaging | 2300 kg | 3550 kg |

TORSION SPRING MAKING MACHINE

Equipment for rotational and torsional springs production is able to manufacture:

- Springs of small dimensions and low clamping force for name cards clips, hairpins, clips for clothing, electronics.

- Springs with increased clamping force for hair pins, clothing, office supplies, furniture, tools, scissors and so on. Springs manufactured on this equipment have long hooks at both ends for engaging and fixing. Hooks are formed by bending tool manually. Number of turns of the spring can reach 25.

- Springs of larger diameter wire: Ø1.6-Ø2.5 mm (40 turns of wire) or Ø2.6-Ø4.0 mm (25 turns of wire).

SPECIFICATIONS

| Model | RG-11K | RG-18K | RG-41K |

|---|---|---|---|

| Wire diameter | 0.3-1.2 mm | 1.2-2.2 mm | 2.3-4.5 mm |

| Spring outer diameter | 42 mm | 65 mm | 120 mm |

| The number of coils | Ø0.3-Ø0.7=0.5-28 pcs. Ø0.8-Ø1.2=0.5-13 pcs. | Ø1.2-Ø1.6=28 pcs. Ø1.7-Ø2.2=13 pcs. | Ø2.3-Ø3.0=28 pcs. Ø3.1-Ø3.8=18 pcs. Ø3.9-Ø4.5=8 pcs. |

| Shoulder length | 40 mm × 50 mm | 50 mm × 70 mm | 70 mm × 100 mm |

| Winding direction | clockwise/counter-clockwise | clockwise/counter-clockwise | clockwise/counter-clockwise |

| Performance | 60 Hz: 30,54,84,120 50 Hz: 24,44,69,99 | 60 Hz: 19,32,50,79 50 Hz: 15,26,41,65 | 60 Hz: 2,4,6,9,10,16,26,36 50 Hz: 1,6,3.3,5,7.5,8.3,13,22,30 |

| Basic engine | 1/2 hp | 1 hp | 3 hp |

| Dimensions of equipment | 98 × 63 × 103 cm | 115 × 86 × 113 cm | 166 × 143 × 155 cm |

| Dimensions of equipment in packaging | 120 × 86 × 145 cm | 122 × 92 × 153 cm | 205 × 165 × 194 cm |

| Weight of equipment | 240 kg | 350 kg | 920 kg |

| Weight of Equipment in Packaging | 400 kg | 500 kg | 1250 kg |

GARAGE DOOR SPRING MAKING MACHINE

SPECIFICATIONS

| Model | RG-58-RDS | |

|---|---|---|

| Wire diameter | Ø5-Ø8 mm | |

| Spring length | 100-800 mm | |

| Spring outer diameter | 60-120 mm | |

| Winding direction | clockwise/counter-clockwise | |

| Engine | machine | 5 hp × 2 |

| Hydraulic Press | 5 hp × 2 | |

| Dimensions of equipment | machine | 135 × 95 × 195 cm |

| Hydraulic Press | 130 × 27 × 130 cm | |

| secondary treatment table | 170 × 65 × 82 cm | |

| Dimensions of equipment in packaging | machine | 151 × 125 × 220 cm |

| Hydraulic Press | 102 × 122 × 99 cm | |

| secondary treatment table | 185 × 80 × 120 cm | |

| Weight of equipment | machine | 1710 kg |

| Hydraulic Press | 220 kg | |

| secondary treatment table | 170 kg | |

| Weight of Equipment in Packaging | machine | 2010 kg |

| Hydraulic Press | 350 kg | |

| secondary treatment table | 610 kg | |

OIL SEAL SPRING MAKING MACHINE

SPECIFICATIONS

| Model | RG-206-CNC |

|---|---|

| Wire diameter | Ø0.2-Ø0.6 mm |

| Spring length | 20-280 mm |

| Performance | 40 pcs/ min. |

| Power | 1.75 kW |

| Wire unwinder model | RG-70E |

| Dimensions of equipment | 72 × 95 × 138 cm |

| Dimensions of equipment in packaging | 134 × 77 × 170 cm |

| Weight of equipment | 280 kg |

| Weight of Equipment in Packaging | 560 kg |