OIL CLEANING AND RECOVERY EQUIPMENT

INTELLIGENT HIGH-SPEED OIL RESIDUE SEPARATOR RTS-A SERIES

Application of oil residue separator RTS-AV

The machine has been widely used in solid-liquid separation from concentrated filtering of forming oil for cold heading, drawing oil (liquid), lapping oil (liquid), cutting oil (liquid) and thread rolling oil, etc.

Application of oil residue separator RTS-AIV

The machine has been widely used in solid-liquid separation from online circulation of forming oil (liquid), buffing oil (liquid), phosphating solution and electroplating effluent etc.

Working principle of oil residue separator

After being absorbed into the centrifugal reel for separation in separation area, the substances to be separated will be separated by virtue of different centrifugal forces obtained from the centrifugal field as different mediums in the substance have different specific gravities. The separated clean liquid will be discharged naturally from the oil discharge outlet. The sediment will be discharged automatically after the sediment thickness reaches the desired setting.

Technical Parameters of oil residue separator RTS-A series

| Model | RTS-AV | RTS-AIV |

|---|---|---|

| Filter type | Centrifugal Separation | |

| Sediment Discharging Mode | Automatic Sediment Discharging | |

| Reel capacity | 2,3 L | 1,5 L |

| Maximum Processing Capacity | 100 L/min | 40 L/min |

| Rotation Speed | 5200 rpm | 7200 rpm |

| Centrifugal Force G | 3500G | 5500G |

| Power Supply Voltage | 380V 4P 50Hz / 220V 3P 60Hz | |

| Total Power | 1,2 kW | |

| Main Motor | 1,1 kW 3P 380V / 1.1 kW 3P 220V | |

| Auxiliary Motor | 0,06 kW 4P 380V / 0,06 kW 4P 220V | |

| Inlet Pipe Diameter | 32A | 25А |

| Outlet Pipe Diameter | 80A | 60А |

| Air Pressure Scope | 0.4 - 0.6 Mpa | |

| Starting Mode | Starting with Frequency Converter | |

| Control Panel | Touch Screen | |

| Control Mode | Automatic / Manual | |

| Overall Dimensions | 1000 × 550 × 1600 | 850 × 510 × 1480 |

| Equipment Weight | 245 kg | 200 kg |

OIL REMOVAL MACHINE RT1200-2/3

Application of oil removal equipment RT1200-2/3 series

The equipment has been widely used for cold heading forming work blanks. The cold heading work-pieces are conveyed into the oil removal machine by conveyor in the oil removing machine, the grease and impurities attached on the surface of work pieces are removed by virtue of high-speed centrifugal force. The PLC system is combined with this system and adjusted flexibly in accordance with the production on site, realizing unattended intelligent management and standardized energy saving and environmental protection.

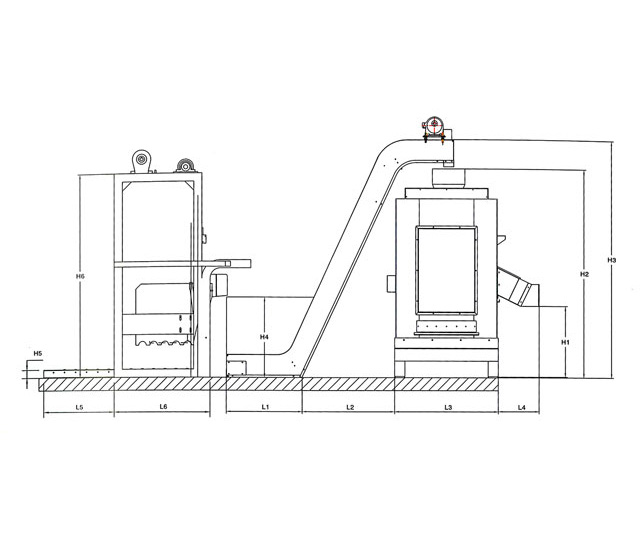

Size Marking

Technical Parameters of Equipment

| Oil Removal Machine | RT1200-2 | RT1200-3 |

|---|---|---|

| Rated Speed | 1450 rpm/ m | 1100 rpm/ m |

| Maximum Capacity | 10 kg / time | 20 kg / time |

| Power Supply Voltage | 380V 4P 50Hz | |

| Rated Power | 1.2 kW/h | 2 kW/h |

| Centrifuge Motor | 0.75 kW/h | 1.5 kW/h |

| Air Pressure Scope | 0.4-0.6 Mpa | |

| Start/Stop Mode | Start/Stop with Frequency Converter | |

| L1 Dimensions | 550 / 1050 / 1500 / 2000 mm | |

| L2 Dimensions | 750 mm | 860 mm |

| L3 Dimensions | 640 mm | 880 mm |

| L4 Dimensions | 340 mm | 340 mm |

| W1 Dimensions | 200 / 260 / 350 mm | 200 / 240 / 280 / 320 mm |

| W2 Dimensions | 96 / 140 mm | 200/ 240 mm |

| W3 Dimensions | 500 mm | 700 mm |

| Control Mode | Automatic Control | |

| Operation Panel | Touch Screen | |

| Conveying Method | Magnetic / Chain Joint / Mesh Belt | Link Joint / Mesh Belt |

| Conveying Motor | 0.2 kW/h | |

| Applicable Nuts | M4 mm - M22 mm | M4 mm - M32 mm |

| Applicable Screws | L≤80 mm φ≤12 mm | L≤120 mm φ≤20 mm |

| W4 Dimensions | 450 mm | |

| H1 Dimensions | 610 mm | 700 mm |

| H2 Dimensions | 1512 mm | 1843 mm |

| H3 Dimensions | 1840 mm | 2100 mm |

| H4 Dimensions | 300 mm - 500 mm (adjustable) | |

| H5 Dimensions | 600 / 800 mm | |

| H6 Dimensions | 1720 mm | |

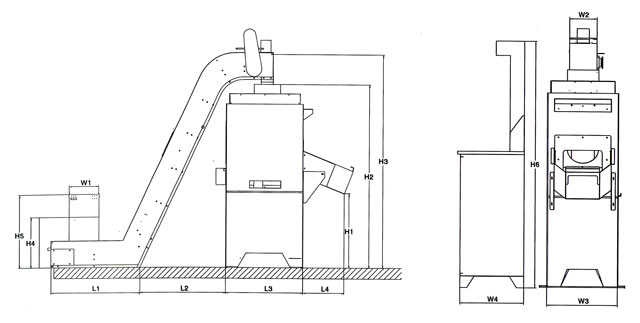

CONCENTRATED OIL REMOVAL SYSTEM RT1200-4

Application of concentrated oil removal system

This system applies to concentrated oil removal in later stage for tapping, thread rolling, anti-rust oil immersing and thermal protection lines, with the advantages of being simple in operation, stable in structure, big in Processing Capacity, standard in site management and saving labor force, etc.

Technical Parameters of Concentrated Oil Removal System

| Rated Speed | 1100 rpm/ m | Control Mode | Automatic Control |

|---|---|---|---|

| Maximum Capacity | 35 kg / time | Operation Panel | Touch Screen |

| Power Supply Voltage | 380V 4P 50Hz | Conveying Method | Magnetic / Chain Joint / Mesh Belt |

| Centrifuge Motor | 2.2 kW/h | Conveying Motor | 0.4 kW/h |

| Air Pressure Scope | 0.4-0.6 Mpa | Applicable Nuts | M4 mm - M22 mm |

| Start/Stop Mode | Start/Stop with Frequency Converter | Applicable Screws | L≤150 mm φ≤50 mm |

| Lift Height | 800 mm | Storage Capacity | 500 kg |

| L1 Dimensions | 550 mm | H1 Dimensions | 700 mm |

| L2 Dimensions | 900 mm | H2 Dimensions | 2040 mm |

| L3 Dimensions | 1020 mm | H3 Dimensions | 2320 mm |

| L4 Dimensions | 400 mm | H4 Dimensions | 780 mm |

| L5 Dimensions | 700 mm | H5 Dimensions | 80 mm |

| L6 Dimensions | 940 mm | H6 Dimensions | 2000 mm |

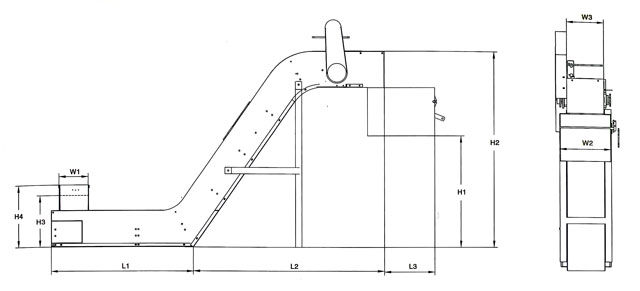

ON-LINE CONVEYOR RTS-SJ18

Size Marking

Introduction of Equipment

Magnetic conveyors have been widely used for small-size products in cold heading/thread rolling/tapping industries. They are fully capable of eliminating the risks of material dropping, blocking and return mixing of traditional conveyor. The link joint or mesh belt conveyors apply to big-size products, and have the advantages of smashing resistance and stability.

Technical Parameters

| Power Supply Voltage | 380V 4P 50Hz |

|---|---|

| Motor Power | 200W / 400W |

| L1 (Tail length) | 750 / 1300 / 1600 / 2000 mm |

| H1 (Discharge point) | 750 mm |

| H2 (Overall height) | 1365 mm |

| H3 (Receiving port) | 250 / 300 mm - 470 mm |

| H4 (Overall height of receiving point) | 470 / 620 mm |

| W1 (Width of Receiving point) | 200 / 300 / 350 mm |

| L3 × W2 × H5 (Storage hopper) | 520 × 370 × 350 mm |

| Opening method for storage hopper | Manual / automatic with cylinder / rotating structure |

| Type of conveyor | Magnetic / link joint or mesh belt |

| W3 Size | 96 / 140 / 120 / 240 mm |

| Color requirements | Blackish green / white |