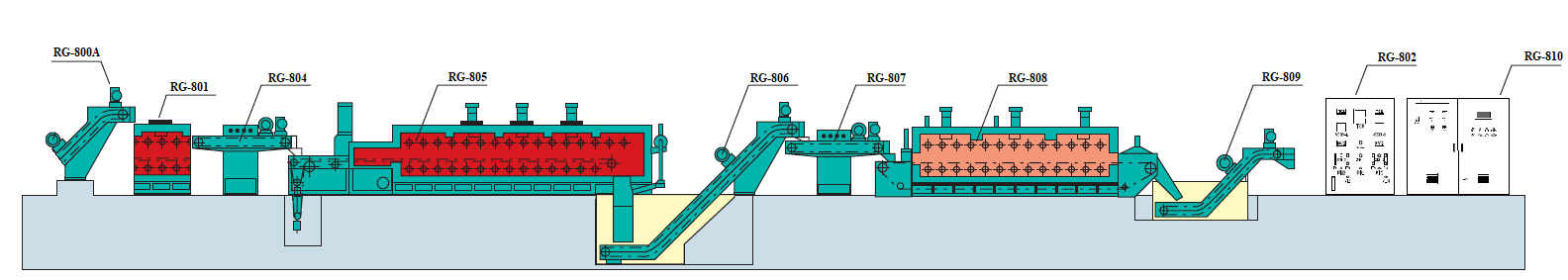

CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

GENERAL INFORMATION ABOUT HEAT TREATMENT CONTINUOUS FURNACE FOR FASTENERS PIT TYPE FURNACE FOR WIRE ANNEALING BELL TYPE FURNACE FOR WIRE ANNEALING CHAMBER FURNACES FOR WIRE ANNEALING VACUUM FURNACE CRUCIBLE FURNACE GENERATORS FOR HEAT TREATMENT SYSTEM

To see the specification of your hardware, click on the appropriate section.

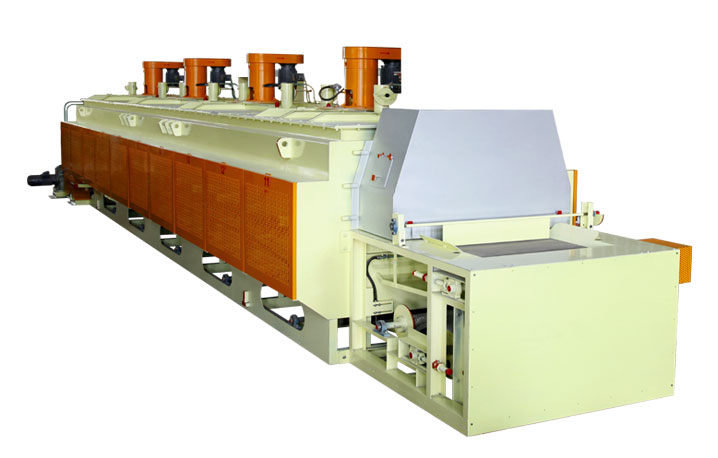

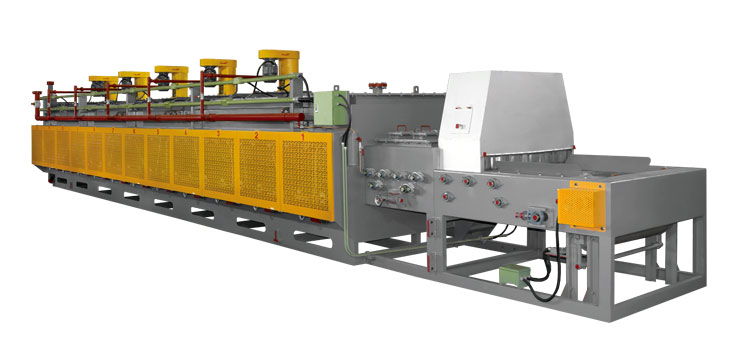

TEMPERING FURNACE WITH CONVEYOR BELT

Application and features of conveyor tempering furnaces

The products are proceeded the tempering treatment at this equipment after passed rear washing machine. Heater adopts up-down design to get uniform temperature and has long service life and low faulty rate. Furnace has mixed fan, makes temperature was uniform in the furnace.

Continuous Electrical Heating Type Hot Blast Tempering Furnace (Low Temp & Open Construction) RG-808A

| Model | Conveyer Width, mm | Inside Height, mm | Length of Heating Section, mm | Inlet Length, mm | Outlet Length, mm | Power, kW |

|---|---|---|---|---|---|---|

| RG-808A-A | 530 | 100 | 3000 | 1500 | 1500 | 51 |

| RG-808A-1 | 530 | 100 | 4000 | 1500 | 1500 | 56 |

| RG-808A-2 | 750 | 100 | 6000 | 1500 | 1500 | 98 |

| RG-808A-3 | 850 | 100 | 6000 | 1500 | 1500 | 121 |

| RG-808A-4 | 1100 | 100 | 6000 | 1500 | 1500 | 132 |

| RG-808A-5 | 1100 | 100 | 8000 | 1500 | 1500 | 161 |

| RG-808A-6 | 1100 | 100 | 10000 | 1500 | 1500 | 176 |

| RG-808A-6S | 1100 | 100 | 12000 | 1500 | 1500 | 225 |

| RG-808A-7 | 1200 | 100 | 10000 | 1500 | 1500 | 187 |

| RG-808A-7S | 1200 | 100 | 12000 | 1500 | 1500 | 239 |

If the Temperature is Under 300°C, then the Reckoning is the Temperature x 80%

Continuous Electrical Heating Type Hot Blast Tempering Furnace (High Temp & Open Construction) RG-808B

| Model | Conveyer Width, mm | Inside Height, mm | Length of Heating Section, mm | Inlet Length, mm | Outlet Length, mm | Power, kW |

|---|---|---|---|---|---|---|

| RG-808B-A | 600 | 100 | 3000/2500 | 1500 | 1500 | 75 |

| RG-808B-1 | 600 | 100 | 4000 | 1500 | 1500 | 110 |

| RG-808B-2 | 700 | 100 | 6000 | 1500 | 1500 | 150 |

| RG-808B-3 | 850 | 100 | 6000 | 1500 | 1500 | 150 |

| RG-808B-4 | 1000 | 100 | 6000 | 1500 | 1500 | 189 |

| RG-808B-5 | 1000 | 100 | 8000 | 1500 | 1500 | 189 |

| RG-808B-6 | 1000 | 100 | 10000 | 1500 | 1500 | 252 |

| RG-808B-6S | 1000 | 100 | 12000 | 1500 | 1500 | 299 |

| RG-808B-7 | 1200 | 100 | 10000 | 1500 | 1500 | 276 |

| RG-808B-7S | 1200 | 100 | 12000 | 1500 | 1500 | 345 |

If the Temperature is Under 650°C, then the Reckoning is the Temperature x 80%

Continuous Electrical Heating Type Hot Blast Tempering Furnace (High Temp & Sealed Construction) RG-808C

| Model | Conveyer Width, mm | Inside Height, mm | Length of Heating Section, mm | Inlet Length, mm | Power, kW |

|---|---|---|---|---|---|

| RG-808C-4 | 1000 | 100 | 7000 | 1500 | 189 |

| RG-808C-5 | 1000 | 100 | 9000 | 1500 | 189 |

| RG-808C-6 | 1000 | 100 | 11000 | 1500 | 252 |

| RG-808C-6S | 1000 | 100 | 12000 | 1500 | 299 |

| RG-808C-7 | 1200 | 100 | 11000 | 1500 | 276 |

| RG-808C-7S | 1200 | 100 | 12000 | 1500 | 345 |

If the Temperature is Under 650°C, then the Reckoning is the Temperature x 80%

Specification & Content of the Equipment of the Electrical Heating Type Tempering Furnace RG-808B-2 (for reference)

Brief Equipment Specification

| Supply Voltage | 220 – 440V 50-60Hz, 3 ph |

| Conveyer Width | 700 mm |

| Inside Height (effective) | 100 mm |

| Length of Heating Section | 6000 mm |

| Inlet Length | 1000 mm |

| Outlet Length (including air cooling system) | 1500 mm |

| Power consumption | 150 kW |

The Composition of the Tempering Furnace

| 1 | Conveyor from stainless steel SUS304 | 1 set |

| 2 | Diffusing fans | 3 sets |

| 3 | Hot-blown System electric Motor 2 hp | 3 pcs |

| 4 | Mixing shaft support and cooling system | 3 pcs |

| 5 | Frequency conversion motor 1 hp | 1 pcs |

| 6 | Reducer 60-100 types of speeds | 1 pcs |

| 7 | Furnace construction materials | 1 unit |

| 8 | Pipe type heating element | |

| 9 | Automatic temperature controller (0-800°C) | 3 sets |

| 10 | Temperature controller materials | 1 unit |

| 11 | Changing the Direction of the Conveyor Notification System | 1 unit |

Continuous Gas Burner Heating Type Hot Blast Tempering Furnace RG-808G (High Temp & Open Construction)

| Model | Conveyer Width, mm | Inside Height, mm | Length of Heating Section, mm | Inlet Length, mm | Combustion Ability, kcal/hr | Power, kW |

|---|---|---|---|---|---|---|

| RG-808G-4 | 1000 | 100 | 6000 | 1500 | 162540 | 6.75 |

| RG-808G-5 | 1000 | 100 | 8000 | 1500 | 162540 | 6.75 |

| RG-808G-6 | 1000 | 100 | 10000 | 1500 | 216720 | 9.75 |

| RG-808G-6S | 1000 | 100 | 12000 | 1500 | 270900 | 12.75 |

| RG-808G-7 | 1200 | 100 | 10000 | 1500 | 258000 | 9.75 |

| RG-808G-7S | 1200 | 100 | 12000 | 1500 | 296700 | 12.75 |

| RG-808G-8 | 1400 | 100 | 12000 | 1500 | 309600 | 13.5 |

If the Temperature is Under 650°C, then the Reckoning is the Temperature x 80%

Continuous Gas Burner Heating Type Hot Blast Tempering Furnace RG-808H (High Temp & Sealed Construction)

| Model | Conveyer Width, mm | Inside Height, mm | Length of Heating Section, mm | Inlet Length, mm | Combustion Ability, kcal/hr | Power, kW |

|---|---|---|---|---|---|---|

| RG-808H-4 | 1000 | 100 | 7000 | 1500 | 300000 | 9.375 |

| RG-808H-5 | 1000 | 100 | 9000 | 1500 | 340000 | 9.375 |

| RG-808H-6 | 1000 | 100 | 11000 | 1500 | 440000 | 11.625 |

| RG-808H-6S | 1000 | 100 | 12000 | 1500 | 540000 | 13.875 |

| RG-808H-7 | 1200 | 100 | 11000 | 1500 | 480000 | 11.625 |

| RG-808H-7S | 1200 | 100 | 12000 | 1500 | 580000 | 13.875 |

If the Temperature is Under 650°C, then the Reckoning is the Temperature x 80%

Specification & Content of the Equipment of the Gas Burner Heating Type Tempering Furnace RG-808G-6S (for reference)

Tempering furnace with an external conveyor belt of heat-resistant wire links RG-808/810B includes:

- Open gas heating system.

- Air mixing device.

- Fans for improved combustion.

- Inlet gas regulator. Exhaust gas moves from the input-output of the furnace and the outlets.

| Maximum temperature of the furnace | 650°C |

| Operating temperature range | 300…650°C |

| Useful width of the furnace | 1000 mm |

| Useful length of the inner space of the furnace | 11000 mm |

| Useful height of the furnace | 100 mm |

| Useful area of the conveyor belt | 0,85 × 13 = 11,05 m2 |

Note: Inner length of the oven, preheating zone, the length of the pipeline at the inlet and outlet of the furnace together account for 13 m, so the useful length of the conveyor belt is 13 m. The density of products layout in the tempering furnace conveyor belt, taking into account the calculation that the product residence time in the furnace is 90 minutes, is not more than 136 kg/m2. | |

| External length of the furnace | 13800 mm |

| Gas heating power | 6,5 kW |

Note: Energy consumption is spent on the operation of gas burners, blowers, servomotors, transformers, solenoid valves. | |

| Power consumed by engines | 7 kW |

| Number of heating zones | 4 |

| Number of gas mixing fans | 4 |

| The residence time of parts in the furnace | 60…180 min. |

Note: Conveyor belts speed range is 40-200 min, the speed is set within this range. | |

| Natural gas consumption | 27…40 m3/h |

Typical Components of Gas Burner Heating Type Tempering Furnace (for reference)

| 1 | Conveyor: width 1,000 mm x inlet height 100 mm x heating length 12,000 mm x inlet length 1,500 mm x outlet length 1,000 mm |

| 2 | Inner insulating materials:

|

| 3 | Heating construction:

|

| 4 | Temperature control system:

|

| 5 | Conveyor belt:

|

| 6 | Mixing fan:

|

| 7 | Max operation temperature: 650°C |

| 8 | Driving system:

|

| 9 | Driving rollers:

|