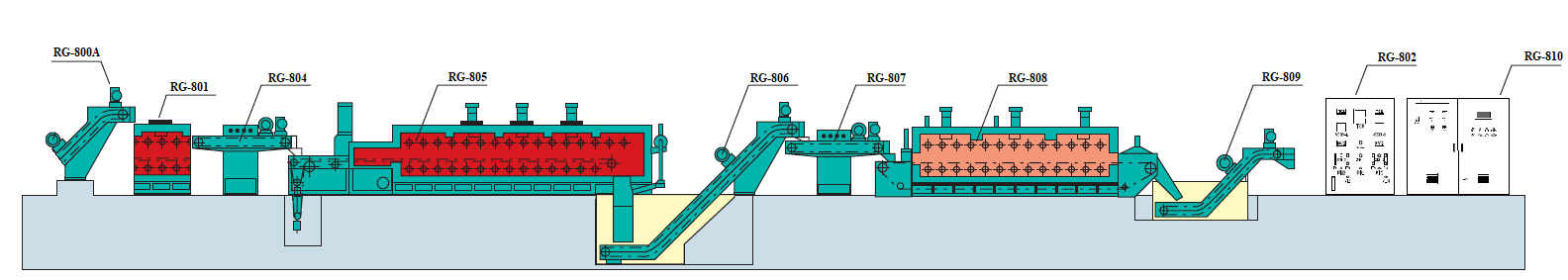

CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

GENERAL INFORMATION ABOUT HEAT TREATMENT CONTINUOUS FURNACE FOR FASTENERS PIT TYPE FURNACE FOR WIRE ANNEALING BELL TYPE FURNACE FOR WIRE ANNEALING CHAMBER FURNACES FOR WIRE ANNEALING VACUUM FURNACE CRUCIBLE FURNACE GENERATORS FOR HEAT TREATMENT SYSTEM

To see the specification of your hardware, click on the appropriate section.

FRONT DEGREASING & WASHING TANK

Application & Features of Front Degreasing & Washing Tank

The products go through the washing & degreasing process before being loaded to the de-phosphating equipment. Two types of front washing and degreasing equipment are available: soaking type and flat type.

The tank has a heater to supply the preheating zone with hot water in the carburizing furnace, in order to save electricity. Front Degreasing and Washing Tank is also equipped with oil and water separator and a powerful air blower. Quenching oil sticks to the material, which lets the quenching oil go back to the oil tank for future reuse.

| Degreasing Area | 60…80°C |

| Phosphate removal Area | 60…80°C |

| Washing zone | 60…80°C |

| Hot air drying zone | 80…100°C |

| For one bath mentioned above, 1 pump and 6 heaters with a total capacity of 78 kW are applied. The heaters are used as spare power sources and only at the beginning of the furnace application (see. Note below); | |

Note: The heat source of the sink is the heat arised from hardening furnace gas burners and its heating system (heating temperature of the water is up to 80 ° C). Design and construction of piping performs by the Buyer according to the scheme provided by the Seller. You also need additional heat exchanger. Heaters in the sink are usually switched off and work only when you start the oven.The washing machine 6 heaters are also installed, 13 kW each | |

Irrigation system for degreasing, washing phosphate removal zones (one system)

| Pumps for irrigation | 1 pcs | |

| Oil separator operates on the principle of densities separation | 1 pcs | |

| Electric heating (13 kW) | 6 pcs | |

| The volume of washing tank | about 2,7 m3 | |

| Engine power | 0,75 kW | |

| The volume of quick-btn-conts for degreasing | about 3 m3 | |

| The volume of quick-btn-conts for phosphate removal | about 3 m3 | |

| The volume of quick-btn-conts for washing | about 3 m3 | |

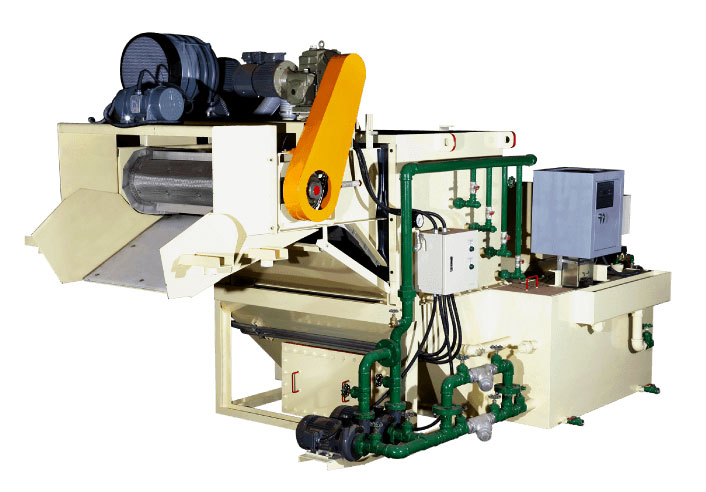

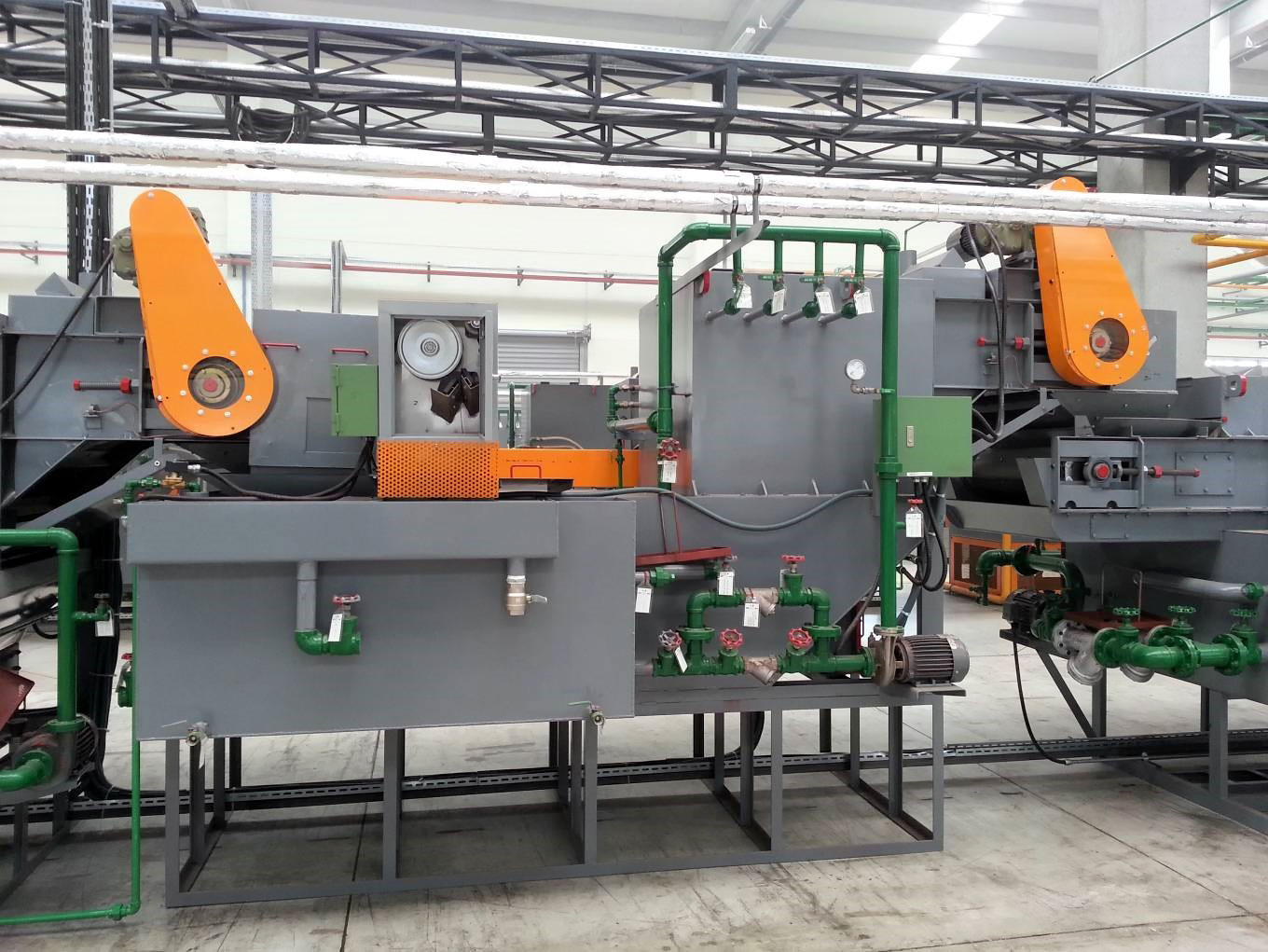

Industrial Design of Soaking-type Washing and Degreasing Equipment

Technical Specifications of Front Degreasing & Washing Tank (Soaking type)

| Model | Conveyor Width, mm | Supplemental Power, kW | Degreasing Tank capacity, l | Degreasing Pump capacity, hp | Outside Dimension, mm | ||

|---|---|---|---|---|---|---|---|

| Width | Height | Length | |||||

| RG-804A-A | 500 | 26 | 1810 | 2 | 1800 | 2345 | 3800 |

| RG -804A-1 | 500 | 26 | 1810 | 2 | 1800 | 2345 | 3800 |

| RG -804A-2 | 500 | 26 | 1810 | 2 | 1800 | 2345 | 3800 |

| RG -804A-3 | 600 | 26 | 2180 | 2 | 1900 | 2345 | 3800 |

| RG -804A-4 | 800 | 26 | 2900 | 2 | 2100 | 2345 | 3800 |

| RG -804A-5 | 800 | 26 | 2900 | 2 | 2100 | 2345 | 3800 |

| RG -804A-6 | 800 | 26 | 2900 | 3 | 2100 | 2345 | 3800 |

| RG-804A-6S | 800 | 26 | 2900 | 3 | 2100 | 2345 | 3800 |

| RG-804A-7 | 1000 | 39 | 3620 | 3 | 2300 | 2345 | 3800 |

| RG-804A-7S | 1000 | 39 | 3620 | 3 | 2300 | 2345 | 3800 |

| RG-804A-8 | 1000 | 39 | 3620 | 5 | 2500 | 2345 | 3800 |

Technical Specifications of Front Degreasing & Washing Tank (Flat type)

| Model | Conveyor Width, mm | Supplemental Power, kW | Degreasing Tank capacity, l | Degreasing Pump capacity, hp | Outside Dimension, mm | ||

|---|---|---|---|---|---|---|---|

| Width | Height | Length | |||||

| RG -804B-A | 500 | 26 | 750 | 2 | 1560 | 2240 | 3100 |

| RG-804B-1 | 500 | 26 | 750 | 2 | 1560 | 2240 | 3100 |

| RG-804B-2 | 500 | 26 | 750 | 2 | 1560 | 2240 | 3100 |

| RG-804B-3 | 600 | 26 | 900 | 2 | 1660 | 2240 | 3100 |

| RG -804B-4 | 800 | 26 | 1200 | 2 | 1860 | 2240 | 3100 |

| RG -804B-5 | 800 | 26 | 1200 | 2 | 1860 | 2240 | 3100 |

| RG -804B-6 | 800 | 26 | 1200 | 3 | 1860 | 2240 | 3100 |

| RG -804B-6S | 800 | 26 | 1200 | 3 | 1860 | 2240 | 3100 |

| RG -804B-7 | 1000 | 39 | 1500 | 3 | 2060 | 2240 | 3100 |

| RG -804B-7S | 1000 | 39 | 1500 | 3 | 2060 | 2240 | 3100 |

| RG -804B-8 | 1000 | 39 | 1500 | 5 | 2260 | 2240 | 3100 |

Components of Front Degreasing & Washing Tank (Soaking type) RG-804

- Washing tank:

- Material: SS41

- Soaking height: 255~300 mm

- Tank capacity: approx. 2,300 liters

- Tank sizes: W1,320 mm × H800 mm × L2,850 mm

- Washing pump: 3HP (2.2KW) with Y type filter (by-pass design) × 1 unit

- Washing conveyor:

- Driving system: 1 HP (0.75KW) motor with gear box (1/450) × 1 unit

- Belt type: Mesh type

- Belt material: Stainless SUS204

- Wires diameter of belt: 1.6mm × 1.6mm

- Belt width: W.800mm × H.30mm

- Belt length: Total 7.8 meters

- Conveyor frame: SS41 steel by strong construction

- Belt chain:

- Type: 05075L

- Materials: Chain plate - stainless SUS304; roller + bush + pin - SCM415, heat-treated

- Heating system:

- Heater type: piping type heater

- Power: 52 KW (13kw/pc × 4 pcs)

- Temperature control : thermostat on-off control

- Skimmer: belt type (0.2kw) × 1 set

- Carrying bar: aluminum in L shape × 1 unit

- Injection pipes (design is patented): 1 unit

- Floor control system proximity switch type × 1 unit

- Pressure meter × 1 set

- Drying blower × 1 set

- Air type

- 3.7 kW (5HP)