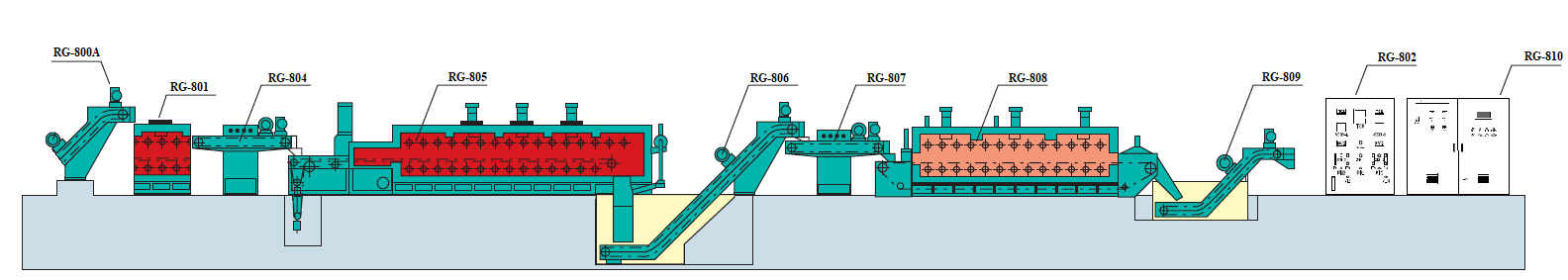

CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

GENERAL INFORMATION ABOUT HEAT TREATMENT CONTINUOUS FURNACE FOR FASTENERS PIT TYPE FURNACE FOR WIRE ANNEALING BELL TYPE FURNACE FOR WIRE ANNEALING CHAMBER FURNACES FOR WIRE ANNEALING VACUUM FURNACE CRUCIBLE FURNACE GENERATORS FOR HEAT TREATMENT SYSTEM

To see the specification of your hardware, click on the appropriate section.

REAR WASHING TANK

APPLICATION AND FEATURES OF SECOND WASHING DEVICE FOR DEGREASING AND RINSING RG807

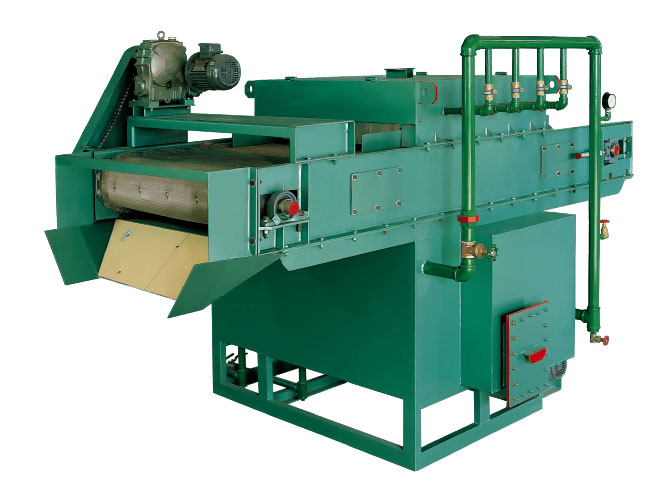

The rear washing device (secondary washing device) is used to rinse and degrease products after the quenching tank before loading into the tempering furnace. Two types of front washing devices are available - immersion and flat type.

Tank has attached with heater to supply hot water with preheating zone in carburizing furnace to save electricity. It has equipped with oil and water separator and strong air blower. Quenching oil will attach on the material that will let quenching oil back to the oil tank for reused.

| Washing zone | 60…80°C |

| Hot air drying zone | 80…100°C |

For 1 bath indicated above one pump and six heaters are applied of 52 kW total power. | |

| Pumps for irrigation | 1 pcs |

| Oil separator operates on the principle of densities separation | 1 pcs |

| Electric heating (13 kW) | 4 pcs |

| The volume of the washing tank | about 2 m3 |

| Engine power | 0,75 kW |

Outlook of the Rear Immersion Degreasing & Washing Machine

Technical Specification of the Electrically Heated Immersion Degreasing & Washing Tank

| Model | Conveyor width, mm | Supporting power, kW | Tank capacity, l | Pumps for circulation and degreasing, HP | External dimensions of the tank, mm | ||

|---|---|---|---|---|---|---|---|

| Width | Height | Length | |||||

| RG-807A-A | 600 | 26 | 2180 | 2 | 1900 | 2345 | 3800 |

| RG-807A-1 | 600 | 26 | 2180 | 2 | 1900 | 2345 | 3800 |

| RG-807A-2 | 700 | 26 | 2540 | 2 | 2000 | 2345 | 3800 |

| RG-807A-3 | 800 | 26 | 2900 | 2 | 2100 | 2345 | 3800 |

| RG-807A-4 | 1000 | 26 | 3620 | 2 | 2300 | 2345 | 3800 |

| RG-807A-5 | 1000 | 26 | 3620 | 2 | 2300 | 2345 | 3800 |

| RG-807A-6 | 1000 | 26 | 3620 | 3 | 2300 | 2345 | 3800 |

| RG-807A-6S | 1000 | 26 | 3620 | 3 | 2300 | 2345 | 3800 |

| RG-807A-7 | 1200 | 39 | 4350 | 5 | 2500 | 2345 | 3800 |

| RG-807A-7S | 1200 | 39 | 4350 | 5 | 2500 | 2345 | 3800 |

| RG-807A-8 | 1400 | 39 | 5070 | 5 | 2500 | 2345 | 3800 |

Technical Specification of the Second Flat Type Degreasing & Washing Tank

| Model | Conveyor width, mm | Supporting power, kW | Tank capacity, l | Pumps for circulation and degreasing, HP | External dimensions of the tank, mm | ||

|---|---|---|---|---|---|---|---|

| Width | Height | Length | |||||

| RG-807B-A | 600 | 26 | 900 | 2 | 1660 | 2215 | 3100 |

| RG-807B-1 | 600 | 26 | 900 | 2 | 1660 | 2215 | 3100 |

| RG-807B-2 | 700 | 26 | 1050 | 2 | 1760 | 2215 | 3100 |

| RG-807B-3 | 800 | 26 | 1200 | 2 | 1860 | 2215 | 3100 |

| RG-807B-4 | 1000 | 26 | 1500 | 2 | 2060 | 2215 | 3100 |

| RG-807B-5 | 1000 | 26 | 1500 | 2 | 2060 | 2215 | 3100 |

| RG-807B-6 | 1000 | 26 | 1500 | 3 | 2060 | 2215 | 3100 |

| RG-807B-6S | 1000 | 26 | 1500 | 3 | 2060 | 2215 | 3100 |

| RG-807B-7 | 1200 | 39 | 1800 | 5 | 2260 | 2215 | 3100 |

| RG-807B-7S | 1200 | 39 | 1800 | 5 | 2260 | 2215 | 3100 |

| RG-807B-8 | 1400 | 39 | 2100 | 5 | 2460 | 2215 | 3100 |

Typical equipment set of the Rear Immersion Degreasing & Washing Tank

| Position | Name | Note |

|---|---|---|

| 1 | Washing bath:

| |

| 2 | Washing Pump power 3 h.p. (2.2 kW) with Y-filter (bypass) | 1 unit |

| 3 | Washing conveyor:

| |

| 4 | Conveyor frame: SS41 steel, reinforced construction | |

| 5 | Conveyor Chain:

| |

| 6 | Heating system:

| |

| 7 | Oil collector: band type power 0.2 kW | 1 set |

| 8 | Support beam: L-shaped aluminum | |

| 9 | Drying blower:

| 1 set |

| 10 | Injection tubes (patented design) | 1 unit |

| 11 | Floor control system: proximity switch | 1 unit |

| 12 | Manometer | 1 set |