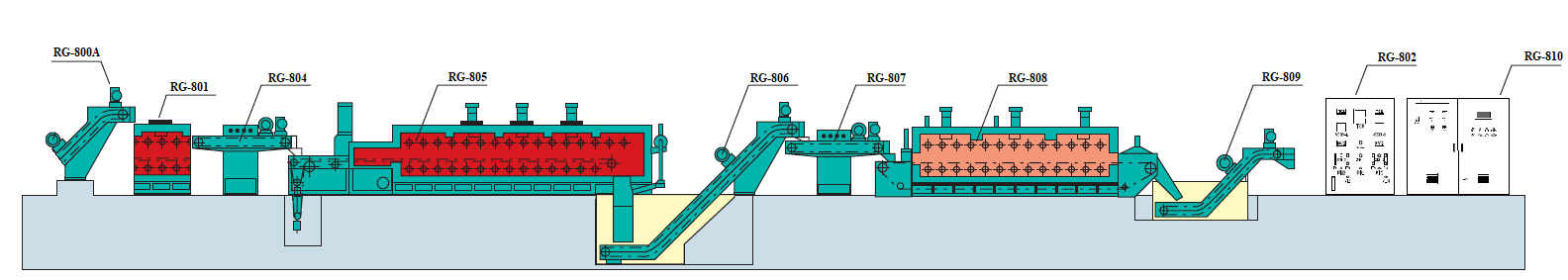

CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

GENERAL INFORMATION ABOUT HEAT TREATMENT CONTINUOUS FURNACE FOR FASTENERS PIT TYPE FURNACE FOR WIRE ANNEALING BELL TYPE FURNACE FOR WIRE ANNEALING CHAMBER FURNACES FOR WIRE ANNEALING VACUUM FURNACE CRUCIBLE FURNACE GENERATORS FOR HEAT TREATMENT SYSTEM

To see the specification of your hardware, click on the appropriate section.

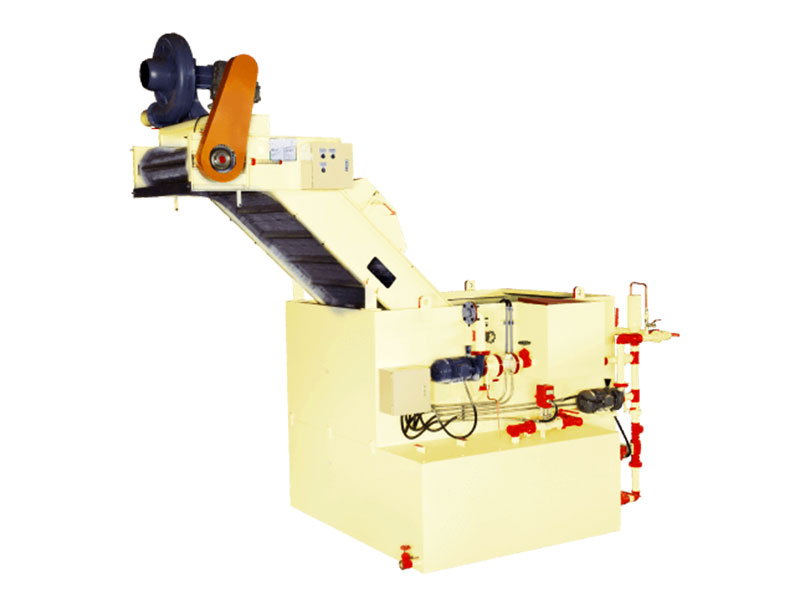

EMULSION COOLING AND ANTI-CORROSION TREATING BATH

Features and composition of the emulsion bath of the series RG-809

Features of construction

- Making use of tempering heat for dyeing to save energy.

- Adopts high-efficiency heat exchanger to prevent fire caused by overheated oil.

- Uses double-layer type cooling tank with circulation pump, and the color of dyeing can be optional.

Emulsion cooling and anti-corrosion treating bath Composition

- Conveyor of wire links for products unloading.

- Outer aqueous emulsion heat exchanger with circulation by pump (the amount of circulating water 60912 l/h).

- SWEP outer heat exchanger (Sweden) - performance 100RT

- Circulation pump (2 hp) for chemicals 1 pcs

- Conveyor chain 1 unit

- Driving engine (1 hp) 1 pcs

- Speed reducer 60-100

Specifications and technical characteristics of emulsion cooling and anti-corrosion treating bath

| Thermal capacity | 304000 kcal/h |

| Total heat exchange area | 10.4 m2 |

| Water flow rate | 60,912 m3/h |

| Oil flow rate | 31320 kg/hr |

| The maximum temperature of the emulsion bath | 50°C |

| The depth of products fall to emulsion environment (from the environment surface to the conveyor belt surface) | 800 mm |

| Unloading belt width | 1000 mm |

| Power spent to the electric heating | very small |

| Power spent by engines | 0,75 kW |

| Amount of circulating water | 60912 l/h |

| Bath volume | about 4000 l |

Scaling during equipment processing must not exceed 3.4 kg per tonne | |

Transverse conveyor for parts unloading from an emulsion bath to the in-plant transport containers includes conveyor belts of wire links | |

| The width of the cross belt conveyor | 500 mm |

| The power consumed by motors | 4,5 kW |

| Approximate speed of unloading | 1500 mm/min |

RG-809A [Single Layer] Cooling Tank Technical Specification

| Model | Conveyer Width, mm | Capacity of Dyeing Tank, L | Dyeing Circulation Pump, hp | Outside Dimension of Dyeing Tank, mm | ||

|---|---|---|---|---|---|---|

| Width | Height | Length | ||||

| RG-809A-A | 800 | 2000 | 2 | 1220 | 1000 | 2450 |

| RG-809A-1 | 800 | 2000 | 2 | 1220 | 1000 | 2450 |

| RG-809A-2 | 800 | 2000 | 2 | 1220 | 1000 | 2450 |

| RG-809A-3 | 800 | 2000 | 2 | 1220 | 1000 | 2450 |

| RG-809A-4 | 1000 | 2500 | 2 | 1530 | 1000 | 2450 |

| RG-809A-5 | 1000 | 2500 | 2 | 1530 | 1000 | 2450 |

| RG-809A-6 | 1000 | 2500 | 3 | 1530 | 1000 | 2450 |

| RG-809A-6S | 1000 | 2500 | 3 | 1530 | 1000 | 2450 |

| RG-809A-7 | 1200 | 2830 | 3 | 1730 | 1000 | 2450 |

| RG-809A-7S | 1200 | 2830 | 3 | 1730 | 1000 | 2450 |

| RG-809A-8 | 1400 | 3150 | 5 | 1930 | 1000 | 2450 |

RG-809B [Double Layer] Cooling Tank Technical Specification

| Model | Conveyer Width, mm | Capacity of Dyeing Tank, L | Dyeing Circulation Pump, hp | Outside Dimension of Dyeing Tank, mm | ||

|---|---|---|---|---|---|---|

| Width | Height | Length | ||||

| RG-809B-A | 800 | 2000 | 2 | 1220 | 1000 | 2450 |

| RG-809B-1 | 800 | 2000 | 2 | 1220 | 1000 | 2450 |

| RG-809B-2 | 800 | 2000 | 2 | 1220 | 1000 | 2450 |

| RG-809B-3 | 800 | 2000 | 2 | 1220 | 1000 | 2450 |

| RG-809B-4 | 1000 | 2500 | 2 | 1530 | 1000 | 2450 |

| RG-809B-5 | 1000 | 2500 | 2 | 1530 | 1000 | 2450 |

| RG-809B-6 | 1000 | 2500 | 3 | 1530 | 1000 | 2450 |

| RG-809B-6S | 1000 | 2500 | 3 | 1530 | 1000 | 2450 |

| RG-809B-7 | 1200 | 2830 | 3 | 1730 | 1000 | 2450 |

| RG-809B-7S | 1200 | 2830 | 3 | 1730 | 1000 | 2450 |

| RG-809B-8 | 1400 | 3150 | 5 | 1930 | 1000 | 2450 |