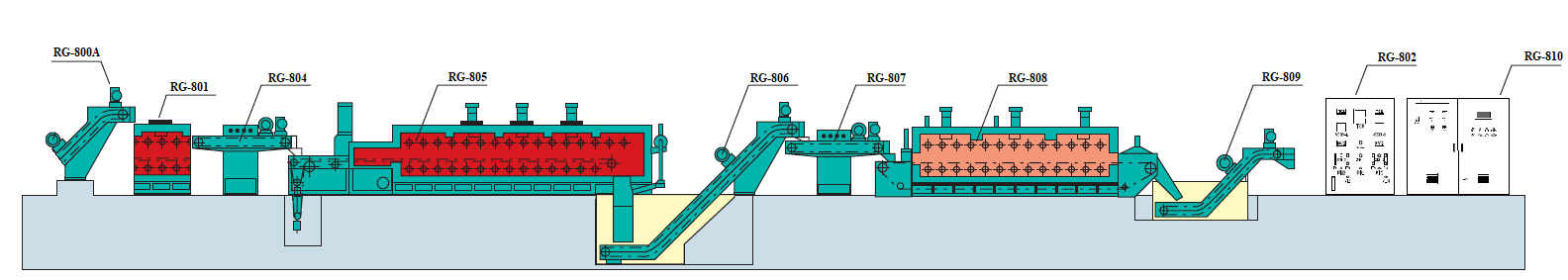

CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

GENERAL INFORMATION ABOUT HEAT TREATMENT CONTINUOUS FURNACE FOR FASTENERS PIT TYPE FURNACE FOR WIRE ANNEALING BELL TYPE FURNACE FOR WIRE ANNEALING CHAMBER FURNACES FOR WIRE ANNEALING VACUUM FURNACE CRUCIBLE FURNACE GENERATORS FOR HEAT TREATMENT SYSTEM

To see the specification of your hardware, click on the appropriate section.

SPARE PARTS FOR CONTINUOUS FURNACE

PERFORMANCE PARTS AND ACCESSORIES TOOLS FOR ONE YEAR OF MACHINE OPERATION

Scope of Delivery

| 1. | Additional conveyor belt of hardening furnace | 1 set. |

| 2. | Self-lubricating bearings for hardening roller | 5 pcs. |

| 3. | Encoder (computer system) | 2 pcs. |

| 4. | Temperature Controller | 1 pcs. |

| 5. | Flame curtain of the hardening furnace | 2 set. |

| 6. | Upper roller of the hardening furnace | 2 pcs. |

| 7. | Lower roller of the hardening furnace | 3 pcs. |

| 8. | Thermocouple tempering furnace | 2 pcs. |

| 9. | O2 sensor | 1 pcs. |

| 10. | Thermocouple of the tempering furnace | 1 pcs. |

| 11. | Ventilator for gas mixing in the tempering furnace | 1 pcs. |

| 12. | Steel scraper conveyor | 2 pcs. |

| 13. | Flame-safe protection for hardening and tempering furnaces burners | 6 pcs. |

| 14. | Spark plug for the hardening furnace | 30 pcs. |

| 15. | Spark plug for the tempering furnace | 10 pcs. |

| 16. | U-shaped radiant tube of the hardening furnace | 3 pcs. |

| 17. | UV flaming sensor (part of the gas burner) | 6 pcs. |

| 18. | Voltage converter of the ignition burner | 4 pcs. |

| 19. | Gas solenoid valve of the burner | 2 pcs. |

| 20. | Burner Servomotor | 1 pcs. |

| 21. | Primary cooling endo gas generator set | 1 pcs. |

| 22. | Nickel catalyst of the endogas generator | 1 container (30 kg) |

| 23. | Fan of the endogas generator mixing pump | 1 set. |

| 24. | Air filter of the endogas generator | 1 pcs. |

Equipment (No. 1 - 24) with fully executed preliminary mounting, with piping and electrical wiring packaged for transportation by sea and land transport.

Not included in scope of delivery

- Unloading and delivery to the site and installing on the foundation, piping.

- Preparation of foundations, installation of protective fencing, supply of all necessary energy and working environment to the connection points.

The following devices and equipment must be installed and prepared by the Purchaser

- Electric cables from the power supply to the transformer, from the transformer to the control panel, from the control panel to the furnace according to the specifications provided by the Seller to the necessary cables and cabling drawings.

- The supply of water and compressed air to the places of connection indicated in the figures provided by the Seller.

- Cooling tower and the entire cooling system according to the drawings provided by the Seller.

Equipment required for installation and start-up

- Power supply: 380V, 50 Hz.

- Natural gas with inlet pressure of at least 100 mbar.

- Propane with inlet pressure of at least 100 mbar

- Technological Nitrogen with inlet pressure of 200 mbar

- Water cooling with inlet pressure of 0.6 ... 2.5 bar (to cool the whole line).

- Cooling water recirculation: continued without pressure.

- Compressed air with adjustable pressure of 5-6 bar.

- Suction system /exhaust pipe.