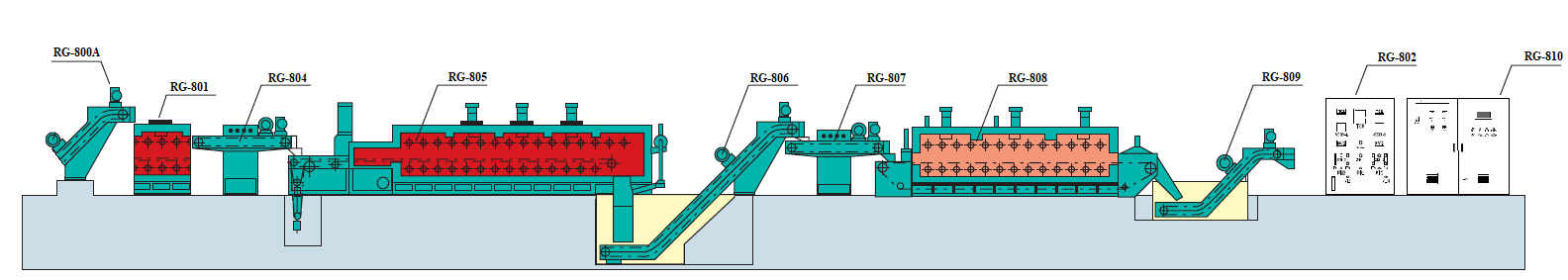

CONTINUOUS FURNACE FOR CARBURIZING, HARDENING AND TEMPERING

COMPUTER PROGRAM CONTROL SYSTEM

COMPUTER CONTROL SYSTEM APPEARANCE

Features of computer control functions

The quality of products is determined by the exact parameters, the possibility of obtaining products of different quality when working with different operators is excluded. It is also convenient for the new operator who does not have much experience with this equipment. The cause of the quality problem can be easily determined with a parameter recorder.

Special heat treatment know-how is well controlled.

One of the features is that the operation of the furnace does not need to be stopped in case a problem occurs with the computer system. All parameters can be set on the control panels, and then return to the computer control system when it is in order.

Heat treatment process automated control computer system has the following features:

- software control of heat treatment unit technological parameters

- data archiving

- certification of processed fasteners

- working out emergency and abnormal situations

- self test

- there is a special electronic media with software archive

Password protection of heat treatment parameters

The software inside parameters are defined into 3 grades by the password:

- Operator: only can inspect parameters of heat treatment, can’t change parameters.

- Chief of heat treatment: can change parameters of heat treatment, can’t save the parameters.

- Manager of heat treatment: can change parameters of heat treatment & save the parameters.

Recording function feature

All parameters of heat treatment of products and the quality can be easily found, for comparison with the requirements of QS 9000 certification.

Management System Capabilities

- All conveyor speed setting.

- All temperature & carbon potential setting

- Indicated curve of every zones temperature & carbon potential

- Indicated whole-set furnace situation by both of normal & abnormal including :

- All temperature situations

- All motors situation

- All pump situation

- Recorder all parameters including:

- Temperature setting.

- Carbon potential setting.

- Curve of every zones & furnace carbon potential.

Remark: the QC result will be allowed to key-in & saving with above parameter record - Different products inside the furnace can be set to different temp., carbon potential & speed according to products, it’s automatic to follow up the products position & change furnace parameters.

- Loading & un-loading indicator & alarm.

- Indicates products position inside the furnace.