COLD FORMING EQUIPMENT FOR SELF-TAPPERS AND SCREWS

BOLT FORMER NUT FORMER PARTS FORMER OPEN DIE REHEADER COMPLEX FASTENERS FORMER SELF TAPPERS AND SCREWS FORMER MICRO SCREWS FORMER HEADING OF LONG PRODUCTS STUD FORMER RIVET HEADING WASHERS PRESS COLD-HEADING OF HOLLOW PRODUCTS

COMPLIANCE OF PRODUCTS AND EQUIPMENT

Equipment Specification

Cold heading machine in protective housing Model RA-2C

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-2C | 0.8~3 mm | 24 mm | 38 mm | 190~220 | 20 mm | 13.5 mm | 18 mm | 18 mm | 1 HP | ¼ HP | 165 × 110 × 156 | 860 | 930 |

Cold heading machine in protective cover Model RA-5.5C

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-5.5C | 2~3.5 mm | 28 mm | 46 mm | 200~250 | 25 mm | 13.5 mm | 18 mm | 18 mm | 1 HP | ¼ HP | 175 × 115 × 185 | 980 | 1050 |

Cold heading machine in protective housing Model RA-10C

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-10C | 2~4 mm | 32 mm | 58 mm | 190~220 | 30 mm | 15 mm | 24 mm | 20 mm | 2 HP | ¼ HP | 185 × 130 × 200 | 1060 | 1360 |

Cold heading machine in protective housing Model RA-15C

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-15C | 4~5 mm | 64 mm | 92 mm | 150~180 | 34.5 mm | 19 mm | 31 mm | 31 mm | 2 HP | ¼ HP | 198 × 130 × 175 | 1930 | 2130 |

| 76 mm | 110 mm | 2030 | 2230 |

Cold heading machine in protective housing Model RA-20C

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-20C | 4~6 mm | 76 mm | 124 mm | 80~100 | 45 mm | 25 mm | 36 mm | 36 mm | 3 HP | ¼ HP | 240 × 140 × 150 | 2775 | 2280 |

| 102 mm | 160 mm | 265 × 140 × 188 | 3250 | 3400 |

Cold heading machine in protective housing Model RA-25C

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-25C | 4~8 mm | 102 mm | 160 mm | 65~85 | 60 mm | 32 mm | 38 mm | 38 mm | 7 ½ HP | ¼ HP | 350 × 160 × 180 | 4500 | 4650 |

Thread Rolling Machine in protective housing Model RG-15THC

| Model | Max. blank diameter | Max.blank length | Performance, pcs./min. | Die dimension | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|

| RG-15THC | 2-6 mm | 64 mm | 200~300 | 25 × 70 × 76~90 25 × 70 × 90~105 | 5 HP | ¼ HP | 197 × 155 × 167 | 1650 | 1800 |

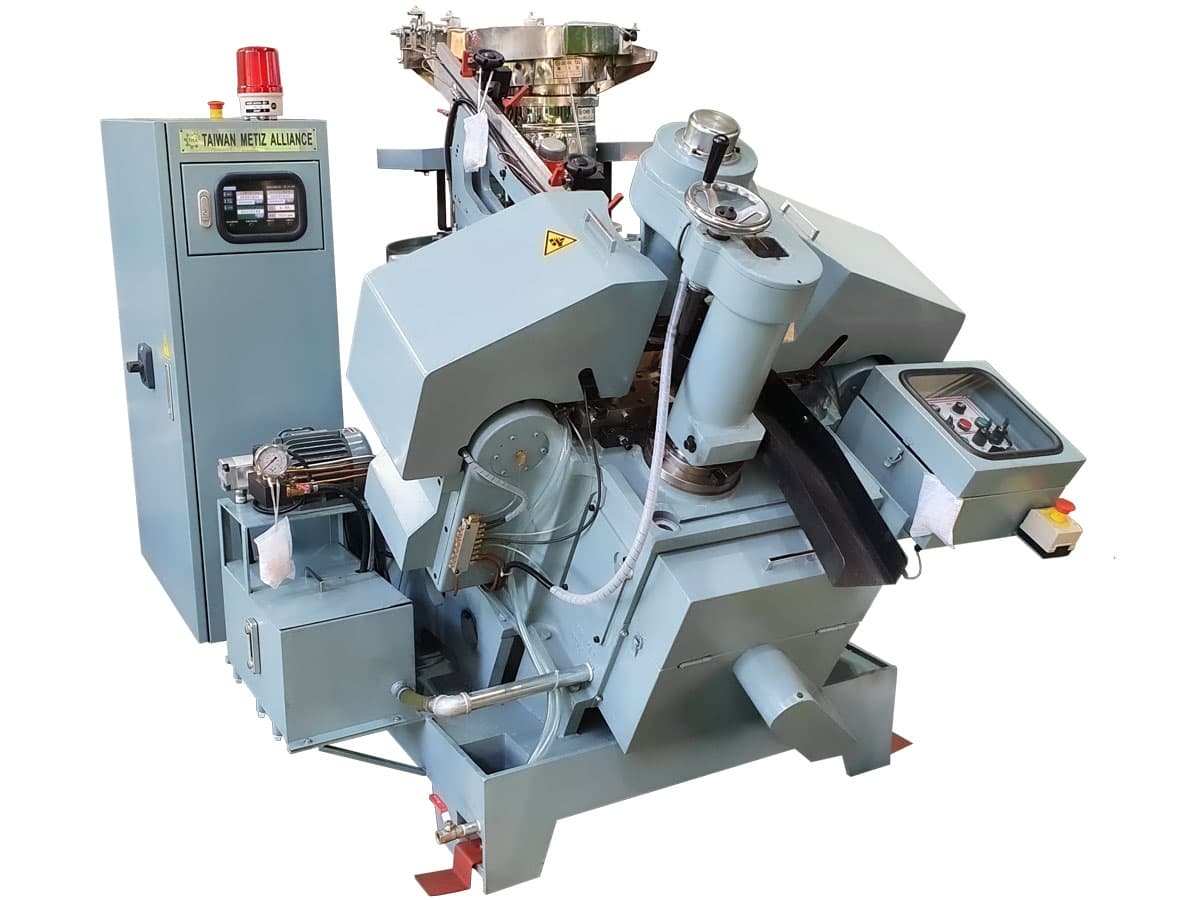

Equipment for the formation of the drill Model RG-235

| Model | Max. blank diameter | Max.blank length | Performance, pcs./min. | Die dimension | Main motor power | Speed Regulation | Control | Blank Feeding | Machine Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RG-235 | 2.8-6.3 mm | 9.15-220 mm | 100~500 | 25 × 102 × 127~1405 | 10 HP / 7.5 кВт / 6 фаз | inverter | AUTO (PLC) | Bowl Vibrator, Ø720 mm | 200 × 240 × 200 | 2520 | 2845 |

Product Specification

Screw with countersunk flat head and double-start thread

| Cold heading of a workpiece + Thread rolling RA-10C + RG-15THC | Weight 1000 pcs. /kg. |

|---|---|

| 3.5 × 19 | 1.15 |

| 3.5 × 25 | 1.35 |

| 3.5 × 32 | 1.62 |

| RA-15C + RG-15THC | Weight 1000 pcs. /kg. |

| 3.5 × 35 | 1.79 |

| 3.5 × 41 | 2.02 |

| 3.5 × 45 | 2.2 |

| 3.5 × 51 | 2.45 |

| 3.5 × 55 | 2.68 |

| 3.5 × 65 | 3.56 |

Screw with countersunk flat head and single-start thread

| Cold heading of a workpiece + Thread rolling RA-10C + RG-15THC | Weight 1000 pcs. /kg. |

|---|---|

| 3.5 × 19 | 1.15 |

| 3.5 × 25 | 1.35 |

| 3.5 × 32 | 1.62 |

| RA-15C + RG-15THC | Weight 1000 pcs. /kg. |

| 3.5 × 35 | 1.79 |

| 3.5 × 41 | 2.02 |

| 3.5 × 45 | 2.2 |

| 3.5 × 51 | 2.45 |

| 3.5 × 55 | 2.68 |

| 3.5 × 65 | 3.56 |

Round Washer Head Sharp Point Screw for metal work

| Cold heading of a workpiece + Thread rolling RA-15C + RG-15THC | Weight 1000 pcs. /kg. |

|---|---|

| 4.2 × 13 | 1.54 |

| 4.2 × 14 | 1.64 |

| 4.2 × 16 | 1.75 |

| 4.2 × 19 | 1.85 |

| 4.2 × 25 | 2.23 |

| 4.2 × 32 | 2.71 |

| 4.2 × 41 | 3.24 |

| 4.2 × 51 | 4.23 |

Round Washer Head Self Drilling Screw for metal work

| Cold heading + Thread rolling + Drill Forming RA-15C + RG-15THC + RG-235 | Weight 1000 pcs. /kg. |

|---|---|

| 4.2 × 13 | 1.82 |

| 4.2 × 14 | 1.91 |

| 4.2 × 16 | 2.08 |

| 4.2 × 19 | 2.22 |

| 4.2 × 25 | 2.61 |

| 4.2 × 32 | 3.12 |

| 4.2 × 41 | 3.81 |

| 4.2 × 51 | 4.61 |

Countersunk Flat Head Wood Screw and Drywall Screw

| Cold heading of a workpiece + Thread rolling RA-10C + RG-15THC | Weight 1000 pcs. /kg. |

|---|---|

| 3.5 × 12 | 0.61 |

| 3.5 × 16 | 0.75 |

| 3.5 × 20 | 0.91 |

| 3.5 × 25 | 1.12 |

| 3.5 × 30 | 1.30 |

| RA-15C + RG-15THC | Weight 1000 pcs. /kg. |

| 3.5 × 35 | 1.50 |

| 3.5 × 40 | 1.75 |

| 3.5 × 45 | 2.02 |

| 3.5 × 50 | 2.28 |

Recommendations for materials for the production of self-tapping screws

For the production of self-tapping screws, SAE 1022 or SAE 1018 wire is recommended. The numbers at the end of the markings 22 and 18 indicate the carbon content of the steel in hundredths. For large threading angles, a material with a higher carbon content is recommended.

Wire Features:

| Chemical composition | ||||||

|---|---|---|---|---|---|---|

| C. Max | Si. Max | Mn. Max | P. Max | S. Max | Al. Max | |

| 1022 | 0.18-0.23 | 0.10 | 0.70-0.90 | 0.030 | 0.050 | 0.020 |

| 1018 | 0.15-0.20 | 0.10 | 0.60-0.90 | 0.030 | 0.050 | 0.020 |

| Mechanical characteristics | |||

|---|---|---|---|

| Diameter, mm | Tensile strength, kg/mm2 | Hardness, НВ | |

| 1018 | 3.5 | 42-50 | 135-165 |

| 1018 | 2.75 | 44-54 | 145-175 |

| 1022 | 3.5 | 42-51 | 135-170 |

| 1022 | 2.75 | 45-55 | 145-175 |