COLD HEADING SELF-TAPPING, SCREW MAKING MACHINES

BOLT FORMER NUT FORMER PARTS FORMER OPEN DIE REHEADER COMPLEX FASTENERS FORMER SELF TAPPERS AND SCREWS FORMER MICRO SCREWS FORMER HEADING OF LONG PRODUCTS STUD FORMER RIVET HEADING WASHERS PRESS COLD-HEADING OF HOLLOW PRODUCTS

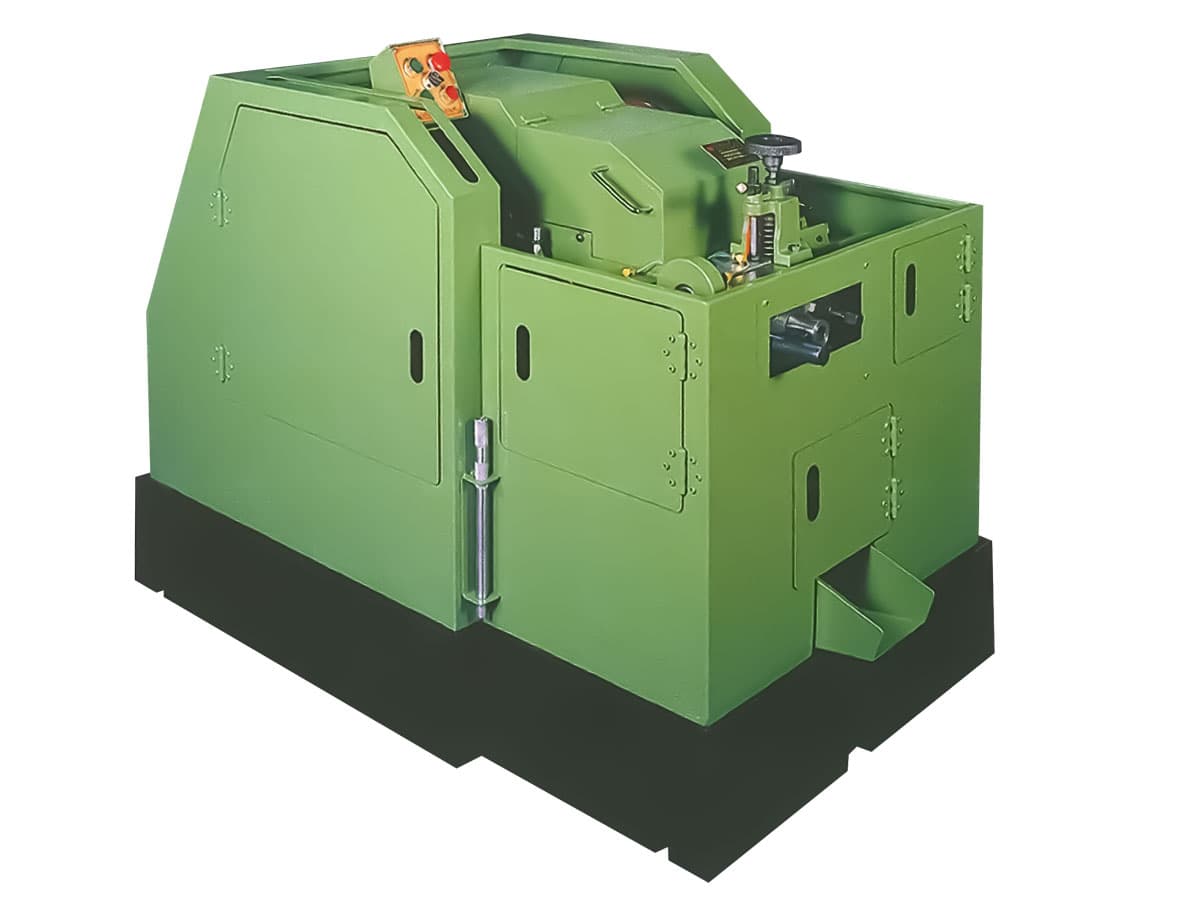

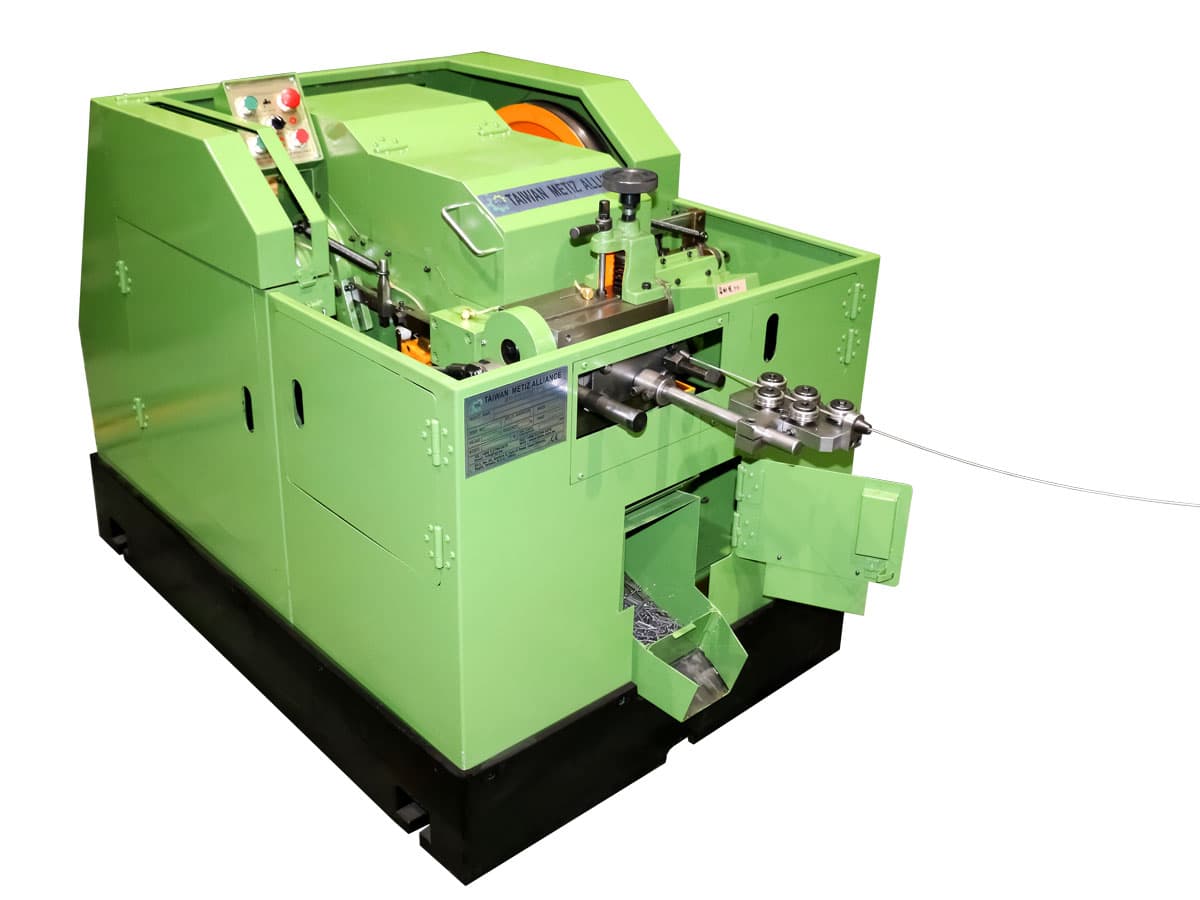

COLD HEADING MACHINE FOR SELF TAPPING SCREWS (IN A SEMI-PROTECTION COVER)

Models of cold heading equipment for the production of screws with semi-protection cover is relatively easier to operate compared to models in a protective cover, and more environmentally friendly. Currently, this equipment is the most popular choice among our clients. Cold forging equipment for the semi-protective cover are represented by machines of large and medium size, ideal for the production of high-quality large and microscopic screws used in machinery, automotive, photo-electronics, precision electronics (iPhone), electrical engineering, automotive industry and others. Fasteners of this equipment can withstand shock and vibration.

Advantages of our cold heading machines

- The solid bed is made of high quality steel imported from Japan. The dimensions of the bed are larger than those of similar machines from other manufacturers, which ensures reliable stability of the machine during operation.

- The cold heading machines are controlled by an automatic control system.

- CE Noise Compliant - Low-noise machines. The full protective cover also provides dust protection and safety for the operator.

- The power consumed by the motors of the machine is relatively small, which saves energy.

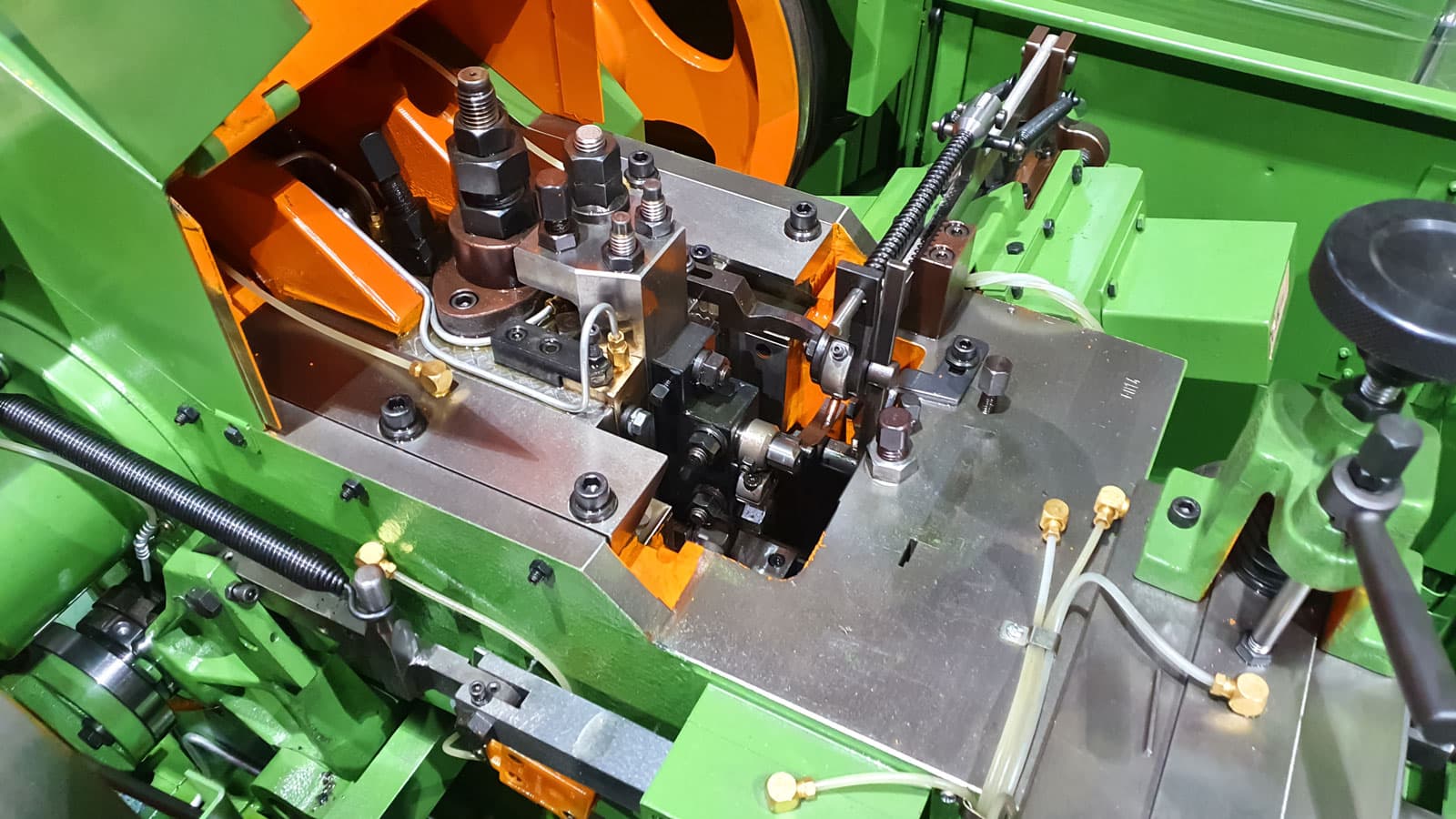

- Faster and more convenient tool changing system compared to other manufacturers' equipment - tool changes for the upsetting machine can be done in less than 30 minutes.

- The simple, convenient design of the machines makes it possible to replace any part of the machine without completely opening and disassembling the machine mechanism, which favorably distinguishes our machines from machines from other manufacturers, including Taiwanese ones.

- The entire process of production and assembly of machines is made in Taiwan, which guarantees the quality of the materials used and strict control over the production of equipment.

- With constantly developing technologies, stability, quality, long-term precision in work are in great demand. The latest equipment for the production of machine tools is used, equipped with computer analysis and verification systems, which ensures the ideal technical characteristics of the machines produced.

Complete set of cold heading machines

The set of each cold heading machine includes:

- 1 set of machine tools

- Wire unwinder

- Automatic counting device

- Work lighting

- Maintenance tools

- Passport

- Operation manual in English

- Electrical cabinet (with protection class IP 64)

- Security door with power cut-off and automatic shutdown system (option)

- Inverter (optional)

Cold heading equipment for self tapping screws in a semi-protection cover RA-5S

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-5S | 0.8~3 mm | 24 mm | 38 mm | 170~200 | 20 mm | 13.5 mm | 18 mm | 18 mm | 1 HP | ¼ HP | 165 × 110 × 156 | 820 | 880 |

Cold heading equipment for self tapping screws in a semi-protection cover RA-5.5S

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-5.5S | 2~3.5 mm | 28 mm | 46 mm | 200~250 | 25 mm | 13.5 mm | 18 mm | 18 mm | 1 HP | ¼ HP | 175 × 115 × 155 | 980 | 1050 |

Cold heading equipment for self tapping screws in a semi-protection cover RA-10S

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-10S | 2~4 mm | 32 mm | 58 mm | 190~220 | 30 mm | 15 mm | 24 mm | 20 mm | 2 HP | ¼ HP | 185 × 130 × 172 | 1050 | 1160 |

Cold heading equipment for self tapping screws in a semi-protection cover RA-15S

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-15S | 4~5 mm | 64 mm | 92 mm | 150~180 | 34.5 mm | 19 mm | 31 mm | 31 mm | 2 HP | ¼ HP | 2100 × 110 × 132 | 1750 | 1840 |

| 76 mm | 110 mm | 1860 | 1980 |

Cold heading equipment for self tapping screws in a semi-protection cover RA-20S

| Model | Max. blank diameter | Max.blank length | Stroke Length | Performance, pcs./min. | Main die diameter | Cut-off Die diameter | First Punch diameter | Second Punch diameter | Main motor power | Oil pump power | Size, L × W × H, sm | Net Weight, kg | Gross Weight, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RA-20S | 4~6 mm | 76 mm | 124 mm | 90~110 | 45 mm | 25 mm | 36 mm | 36 mm | 3 HP | ¼ HP | 240 × 140 × 150 | 2645 | 2750 |

| 102 mm | 160 mm | 80~100 | 265 × 150 × 150 | 3210 | 3360 |