Equipment for metal hardware, fasteners and component parts сold production

TECHNOLOGY OF FASTENERS PRODUCTION

(for reference)

In the automobile and tractor industry almost all fasteners are made by cold heading. Cold heading is used for forming the heads of bolts, screws, rivets in mass-production. In this way, they produce more complex parts (eg. ball and stepped fingers, rollers and ball bearings, etc.). Calibrated steel rods with diameter of 0.6 to 38 mm, as well as rods of non-ferrous alloys (aluminum, copper, etc.) of round, hexagonal and other forms of cross-section are subjected to cold heading.

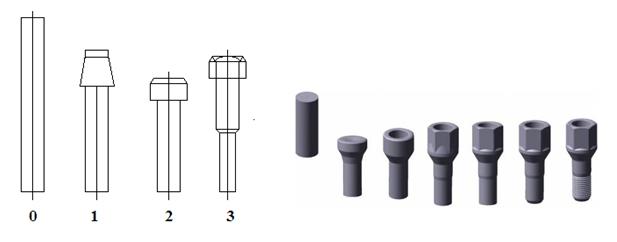

Cold heading as a rule is performed on the cold heading press machines (usually horizontal, single-stroke or multi-position). Following the feeding of the material (plastic thread) through the cutting die, knife cuts the blank and transfers it to heading line. Punch leads the blank to the die, and after the blank stops the ejector performs blank head heading. When the punch returns to the initial position headed part is removed from the die by the ejector and heading cycle repeats. If the head cannot be headed with a single stroke of the punch, heading is carried out at two, three or more stroke (multi-position) cold heading machines (Fig. 1). Performance of modern heading machines id up to 400 parts per minute.

Positions: 0 – blank length; 1 - pre-heading; 2 - final heading; 3 – reduction for threading and edges cutting.

SCREW PRODUCTION

MINIMUM SET OF EQUIPMENT FOR SCREW PRODUCTION

The minimum set of equipment for the production of screws includes two models of the equipment:

- The equipment for cold heading of screws. It is used to form blanks (base) for the screw. At this stage, cold heading machine cuts the wire rod to the desired length, forms the screw head, the tip, and a slot length. Screw diameter is determined by the diameter of the wire used. Thereafter, the blank is transmitted to the second machine (thread rolling), which serves for thread rolling and forming a sharp tip.

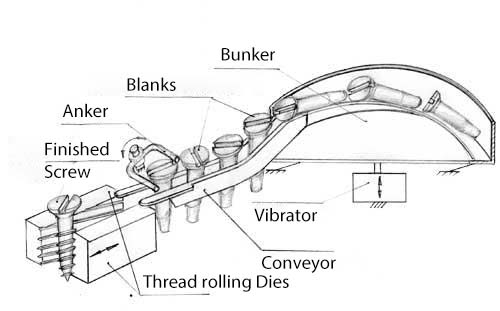

- Thread rolling machines for screws. Threading is performed on special machines. The screw blanks are filled into the hopper. From the hopper via the vibratory conveyor and the anchor mechanism blanks come into the threading zone. However, they are strictly oriented towards the working elements. Working elements are flat dies. They are moved towards and parallel to each other and perpendicular to the axis of the screw, wherein the dies are pressed tightly to the shaft of the screw. Dies are manufactured according to the basic parameters of the screws threads. In Russia, according to the metric version. Foreign manufacturers may use dies for cutting inch threads on the screws. Kinematic variant of screws manufacturing is presented in Figure 2.

According to this scheme screws up to diameter of 10-12 mm are produced. Over these diameters screws usually made by hot stamping. An example of this - track screw diameter - 24 mm, length - 170 mm. Further development of the technology of screws production is the technology of self-tappers production.

SELF-TAPPERS PRODUCTION

MINIMUM SET OF EQUIPMENT FOR SELF-TAPPERS PRODUCTION

Self-tapper rightly got its name because the thread is able to cut not only in soft materials such as wood or plastic, but also metal or concrete. The ability to thread of self-tapper is achieved by the fact that its surface is subjected to heat treatment (hardening). In addition, to ensure that self-tapper can be screwed in fastened constructions, its ending is often designed as a drill. This drill when screwing the self-tapper drills a hole of required diameter.

Self-tapper rightly got its name because the thread is able to cut not only in soft materials such as wood or plastic, but also metal or concrete. The ability to thread of self-tapper is achieved by the fact that its surface is subjected to heat treatment (hardening). In addition, to ensure that self-tapper can be screwed in fastened constructions, its ending is often designed as a drill. This drill when screwing the self-tapper drills a hole of required diameter.

For organization of high-quality, competitive production of screws, as a rule, required five models of equipment:

- The equipment for cold heading of self-tappers. To form self-tapper head and the rod from the preform.

- Equipment for the formation of self-tapper top (nib). In order to be optimally screwed in a fastened structure.

- Thread rolling machines for self-tappers. For the formation of threads.

- Hardening furnace for self-tappers. For hardening the surface of ready-made metal self-tappers to impart additional strength and hardness. Self-tappers are hardened up to at least 55 units HRC (Rockwell).

- Equipment for galvanizing (white or yellow zinc), oxidation or phosphatizing self-tappers. To protect self-tappers against corrosion.

- Packaging equipment. Packaging of products in boxes or plastic bags.

The minimum set of equipment for the manufacture of self-tappers includes two models of the equipment:

- The equipment for cold heading of self-tappers. To form self-tapper head and the rod from the preform.

- Equipment for the formation of self-tapper top (nib). . In order to be optimally screwed in a fastened structure.

- Thread rolling machines for self-tappers. For the formation of threads.

- Hardening furnace for self-tappers. For hardening the surface of ready-made metal self-tappers to impart additional strength and hardness. Self-tappers are hardened up to at least 55 units HRC (Rockwell).

- Equipment for galvanizing (white or yellow zinc), oxidation or phosphatizing self-tappers. To protect self-tappers against corrosion.

- Packaging equipment. Packaging of products in boxes or plastic bags.

The minimum set of equipment for the manufacture of self-tappers includes two models of the equipment:

- The equipment for cold heading of self-tappers. To form self-tapper head and the rod from the preform.

- Thread rolling machines for self-tappers. For the formation of threads.

To make an accurate calculation of the cost of equipment for production of self-tappers please send us the detailed specifications of products you want to produce and drawings, namely:

- Fastener Name.

- Head diameter.

- Rod length.

- Performance of the equipment (pcs./min.).

- Products Drawings.

BOLTS PRODUCTION

MINIMUM SET OF EQUIPMENT FOR BOLTS PRODUCTION

The minimum set of equipment for the production of bolts includes two models of the equipment:

- The equipment for bolts cold heading. For the formation of bolt head and rod from the preform.

- Thread rolling machines for bolts. For forming the thread on the bolt rod.

The technological process of manufacturing of fasteners and fastening products is controlled from raw material to finished product packaging. Thus, in the process of fasteners production it is recommended to include the equipment for heat treatment, galvanizing, phosphatizing, automatic quality test equipment, grading and packing equipment for metal hardware, fasteners and component parts.