Stainless Steel Conveyor Belts

Stainless steel belts is a specialized solution engineered to perform reliably in extreme operating environments. Its advanced properties make it especially effective for granulation processes in petrochemical industries, including sulfur, sulfur bentonite, paraffin wax, resin, pitch, urea, and hot melt adhesives.

In the confectionery sector, stainless steel belts are at the heart of candy and chocolate pelletizing systems, ensuring precision and consistency in every batch.

For the seafood industry, tunnel-freezing systems rely heavily on steel belts as their central component. A durable, high-quality belt not only boosts efficiency but also delivers long-term value for large-scale processors.

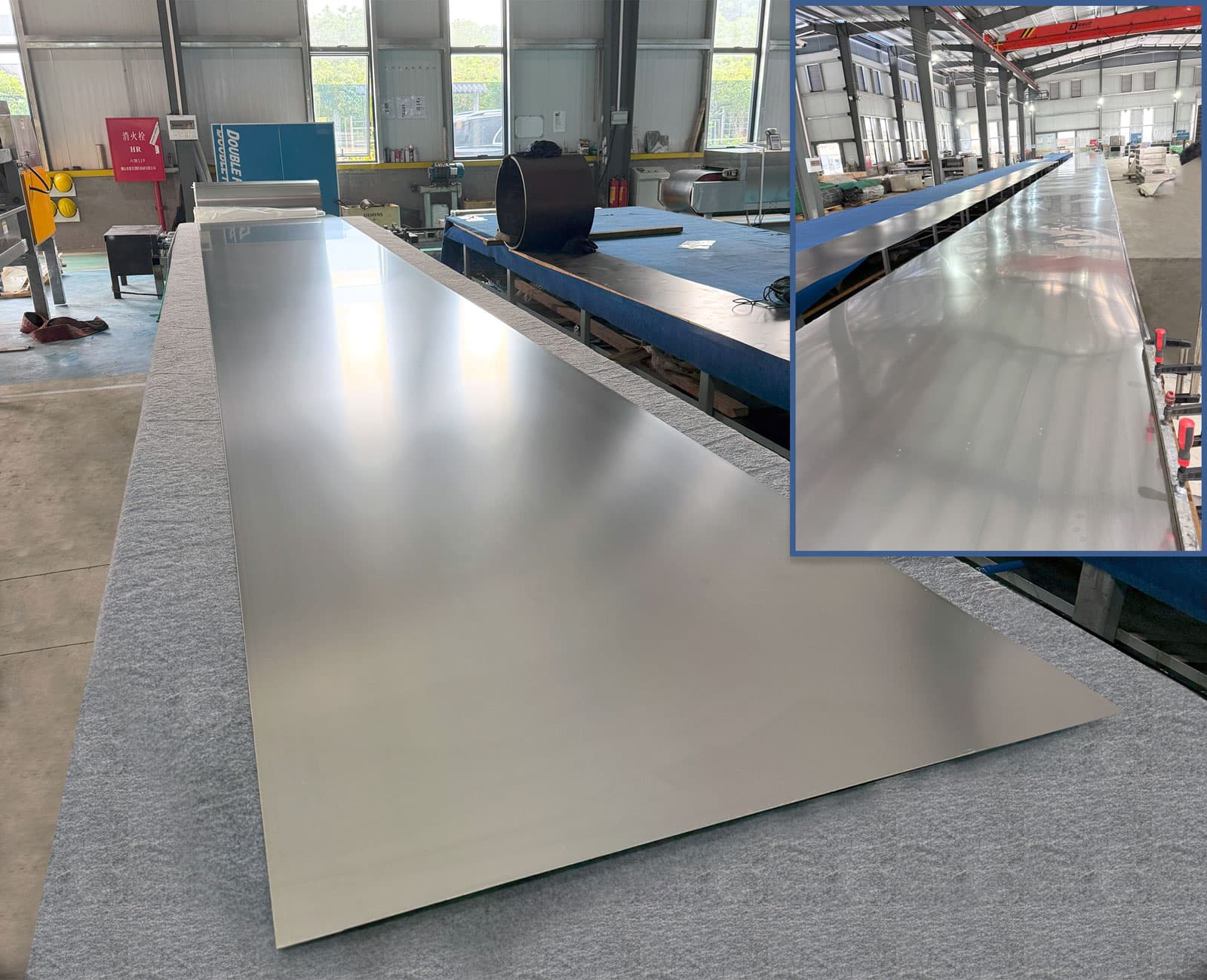

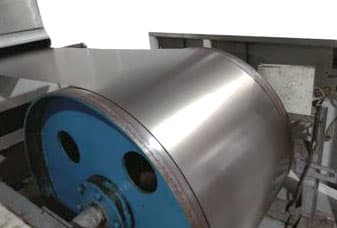

Stainless Steel Conveyor Belt BSN-1200

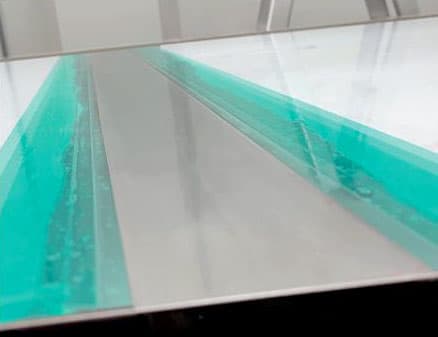

The BSN-1200 stainless steel belt is engineered for extreme environments, making it the ideal choice for tunnel freezers, chocolate cooling, optical film casting, chemical cooling flake and petrochemical granulation. Its durability, hygiene, and efficiency set it apart from conventional belts. This stainless steel conveyor belt combines durability, precision, and scalability, giving manufacturers a reliable conveyor solution that keeps production efficient and competitive.

Key Features

- High toughness and wear resistance.

- High temperature resistance.

- Smooth, corrosion-proof surface.

- Excellent flatness and fatigue strength.

- Superior thermal conductivity for energy savings.

- Hygienic, easy to clean design.

- Stable operation with low vibration.

- Strong mechanical strength and precise tracking.

- Long service life and seamless welding quality.

- Customizable dimensions (up to 2000 mm width, 0.4 - 1.2 mm thickness).

Key Benefits

- Boosted Productivity. Engineered to streamline chocolate cooling and petrochemical granulation, the belt ensures smooth handling of heat and viscosity, supporting large-scale, high-speed production.

- Exceptional Durability. Designed for tunnel freezers and other heavy-duty environments, the BSN-1200 resists wear, fatigue, and corrosion, extending service life while maintaining reliable performance.

- Energy-Efficient Thermal Transfer. With strong conductivity and hygienic construction, the belt ensures quick, efficient cooling or freezing while keeping energy costs under control.

- Precision Operation. Low vibration and stable mechanics guarantee smooth processes, reducing maintenance requirements and ensuring uninterrupted production.

- Custom-Fit Design. Flexible sizing allows easy integration into diverse systems, giving manufacturers the ability to tailor operations without compromising efficiency.

- Future-Proof Investment. Suitable across multiple industries, the BSN-1200 adapts to evolving production demands and provides long-term reliability for scaling businesses.

- Cost-Effective Integration. Designed for seamless system compatibility, the belt not only reduces operational expenses but also strengthens overall production performance.

| Length | Width | Thickness |

|---|---|---|

| Customizable | 2000 mm(No merging) | 0.4/ 0.5/ 0.8/ 1.0/ 1.2 mm |

Endurance in Demanding Conditions

The BSN-1200 belt is built to thrive in harsh settings. Its resilience against wear and corrosion ensures longevity, while its smooth surface preserves hygiene and simplifies maintenance. Seafood processors, in particular, benefit from its reliability in tunnel freezing, where flatness and stability are critical. By delivering excellent thermal conductivity, the belt reduces energy waste and lowers operating costs.

Efficiency in Production

In chocolate cooling and pelletizing, the BSN-1200 stainless belt ensures precise temperature control and seamless solidification. Its capacity for handling heat, viscosity, and large-scale production makes it indispensable for confectionery manufacturers. With custom sizing available, it adapts easily to different systems while maintaining consistent, high-quality results.

Accuracy and Dependability

Every belt is manufactured with exceptional welding standards and reinforced mechanical strength. Its V-shaped guide strip ensures reliable tracking and straight operation, minimizing downtime and preventing product loss. The belt is specifically designed to withstand the demands of continuous operation in both food and industrial environments.

Scalable for Growth

As operations expand, the BSN-1200 belt scales with your production needs. Its flexible, multipurpose design supports industries from seafood and chemicals to chocolate and other food processing. By offering a long-lasting and adaptable conveyor solution, it helps businesses future-proof their production lines and respond quickly to shifting market demand.

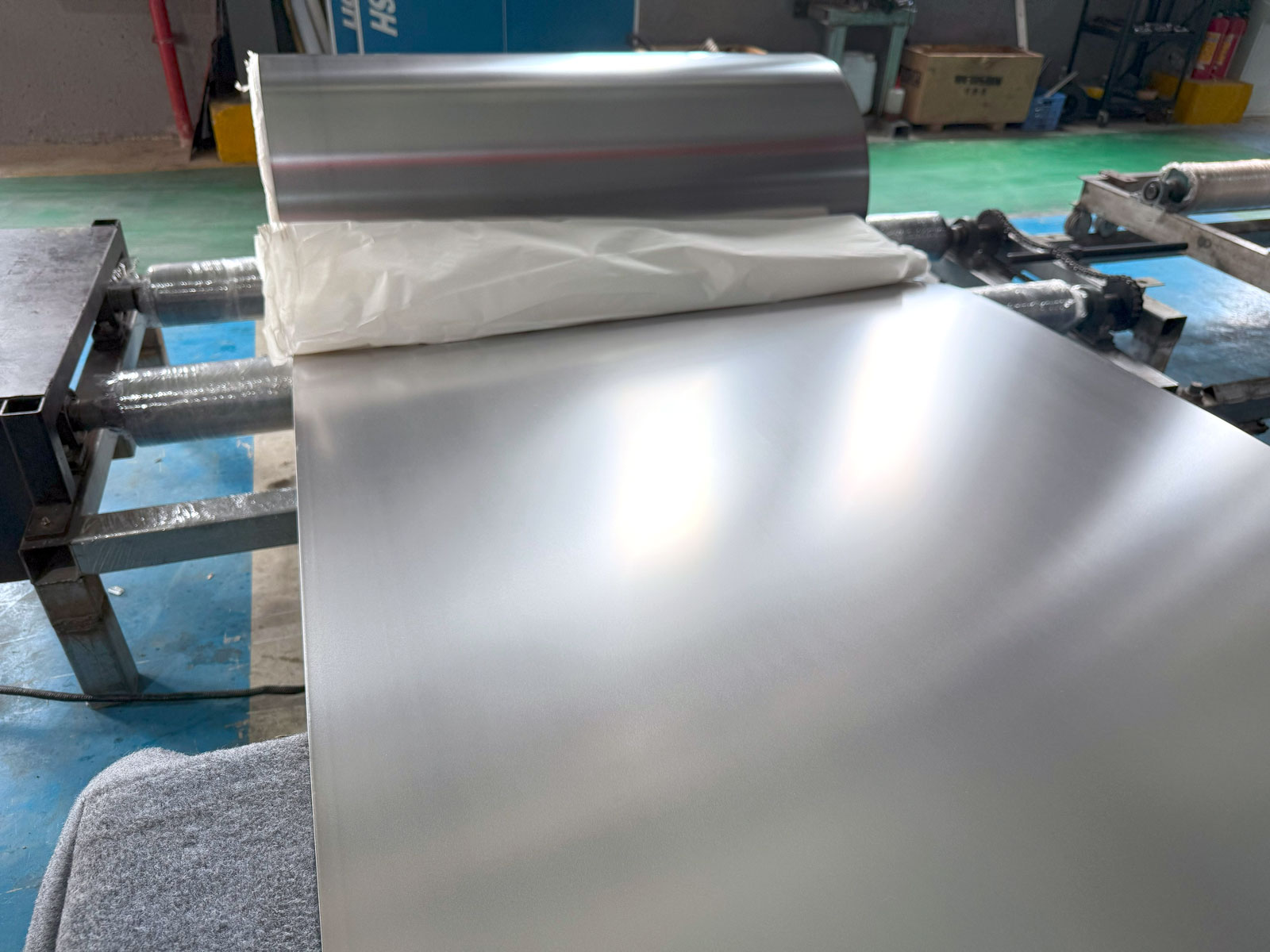

Wire-mesh belt upgrade to steel belt

No Need for New Equipment – Start Making New Products Today!

Conventional ovens rely on wire-mesh conveyors, but these come with many drawbacks: short lifespan, heavy vibration, excessive stretching, difficult cleaning, limited product range, and more. By upgrading to a steel belt conveyor, these issues can be eliminated with ease.

Because steel belts differ in weight, tension, and heat transfer properties, the system must be properly adjusted when making the switch. Without these modifications, problems such as belt misalignment, drum slipping, or even belt deformation and cracking may occur.

To ensure a smooth oven upgrade, our skilled engineering team provides expert support. With fast, cost-effective solutions, we handle the entire transformation process and eliminate the risks caused by insufficient technical know-how.

After Sales Service

Our experienced after-sales service team can provide you with the following professional steel belt services:

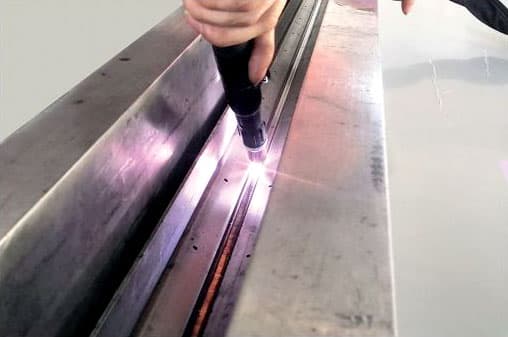

- steel belt welding and installation;

- steel belt interpolation welding;

- steel belt crack repairing;

- adhesive V-rope bunding;

- steel belt dredging;

- mirror belt repairing;

- steel belt cleaning;

- spare parts changing;

- wire-mesh oven upgrading;

- deformed belt repairing.

Seamless Welding Technology

Stainless steel belt welding process is a strong professional technology, which requires professional technicians and installation tools to complete. Good welding quality can greatly improve the stability and service life of steel belt. We have senior engineers with more than 10 years experience can meet almost all kinds of requirements of welding requirements.