Carbon Steel Conveyor Belts

The oven steel belt is the primary conveying medium in tunnel ovens and represents a critical component of the baking line. It has been the standard for over fifty years, widely applied in the production of biscuits, cookies, cakes, and similar baked goods. Despite the availability of mesh belts, steel belts remain indispensable and are steadily replacing mesh alternatives in industrial ovens.

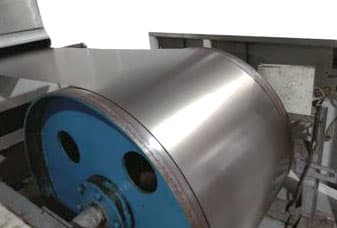

A steel belt conveyor system comprises the belt itself, drive and tension stations, and auxiliary components such as tracking systems, graphite supports, cast-iron blocks, and guide wheels. These additional parts increase system cost compared to mesh-belt ovens. Converting an existing mesh-belt oven to a steel-belt system requires significant design modifications, investment, and downtime.

Steel belts provide nearly all the functional benefits of mesh belts while offering far superior durability. Typical service life exceeds five years, with longevity strongly influenced by oven design precision and operating speed. Lower running speeds significantly extend lifespan: for instance, belts working at running speed 1-2 m/min can last over 10 years, while high-speed chemical granulation belts (up to 140 m/min) may only last 1-2 years. On average, a single steel belt outlasts three mesh belts, making long-term cost performance favorable despite higher initial price

Carbon Steel Conveyor Belt for Baking Process BCR-1300

Carbon Steel Belt Characteristics

The BCR-1300 steel belt is fabricated from tempered hardened carbon steel and exhibits the following characteristic properties:

- high static load-bearing capacity and great static strength;

- exceptional resistance to cyclic fatigue;

- corrosion resistance;

- efficient thermal conductivity;

- superior resistance to wear and repeated stress;

- good flatness, hard and smooth, easy to clean;

- straightforward maintenance and reparability;

- better than wire mesh conveyor belt;

- have certain recycling value.

Dynamic Strength. Under standard testing at 20°C in dry conditions, the base material demonstrates a fatigue limit of +460 N/mm2, defined as the stress level at which 50% of specimens endure 2 million load cycles.

| Length | Width | Thickness |

|---|---|---|

| Customizable | Up to 1500 mm | 0.8 - 1.2 mm |

Carbon Steel Belt Application

The belt surface is hardened and polished, incorporating a thin oxide film. BCR-1300 is predominantly employed in environments of low corrosive activity. Owing to its high thermal transfer capability and uniform heat distribution, it is particularly well adapted to thermal processing operations such as biscuit baking. In addition, it demonstrates reliable performance in heating and drying of liquid, paste, and particulate materials. Carbon steel belt is suitable for cookies, Swiss roll, cake, white lover, chocolate, nuts cake, bread, Italian crispy cakes, muffins, brownie, puff, crackers, oaten cake, ginger bread, cereals, Christmas gingerbread, marin sugar, dragon card, French cake, pizza, sponge cake and other food production processes.

Carbon Steel Belt BCR-1300 Features

- Superior Efficiency and Heat Transfer. The Carbon Steel Belt BCR-1300 is designed for advanced thermal performance in industrial baking. Manufactured from tempered carbon steel, it provides a hardened, uniform surface that ensures precise heat conduction and stable operation at temperatures up to 350°C. This enables consistent product quality, minimizes defective output, and maximizes process efficiency.

- Engineered for Strength and Accuracy. With high static strength, wear resistance, and fatigue tolerance, the BCR-1300 Carbon Steel Belt delivers long service life and minimal downtime. Its seamless integration into existing tunnel oven systems supports a wide range of baked goods, from biscuits to bread, while maintaining process reliability and product uniformity.

- Advantages Over Mesh Belts. Traditional wire mesh belts cannot meet the demands of modern, diversified production. The BCR-1300’s flat, pore-free surface allows uniform heating and gentle handling of fragile products such as cookies, making it the preferred choice for manufacturers seeking consistent results

- Enhanced Physical and Operational Properties. The steel belt’s thermal stability, vibration-free operation, and repairability ensure optimal baking conditions and long-term durability, often exceeding a decade of service. Its smooth surface minimizes contamination, simplifies cleaning, and ensures compliance with high hygiene standards.

- Future-Ready Solution. The steel conveyor belts we supply are is a scalable investment that adapts to evolving production needs, new product trials, and market expansion. Its combination of durability, efficiency, and low maintenance makes it a strategic choice for forward-looking manufacturers.

Corrosion Behavior and Material Limitations

- General corrosion: Although an oxide layer is present, the BCR-1300 remains susceptible to corrosion in aqueous media, especially in acidic solutions. Corrosion rates increase significantly with elevated temperature, fluid velocity, acidity, and salinity. The introduction of chromates(CrO42-) and nitrate(NO3-) will inhibit corrosion in neutral solution.

- Pitting and crevice corrosion: The alloy demonstrates sensitivity to localized corrosion phenomena, particularly in low-oxygen or low-oxidant environments, where pitting and crevice attack are likely to occur.

- Hydrogen embrittlement: BCR-1300 is vulnerable to hydrogen-induced embrittlement when exposed to hydrogen-containing environments. To prevent deterioration of mechanical performance, specialized post-treatment is mandatory under such service conditions.

- Weldability: The material exhibits favorable welding characteristics. Gas-shielded arc welding, with TIG welding as the preferred technique, is recommended. Pre-weld uniform heat treatment should be performed to preserve both static and dynamic mechanical properties of the welded joints.

Wire-mesh belt upgrade to steel belt

No Need for New Equipment – Start Making New Products Today!

Conventional ovens rely on wire-mesh conveyors, but these come with many drawbacks: short lifespan, heavy vibration, excessive stretching, difficult cleaning, limited product range, and more. By upgrading to a steel belt conveyor, these issues can be eliminated with ease.

Because steel belts differ in weight, tension, and heat transfer properties, the system must be properly adjusted when making the switch. Without these modifications, problems such as belt misalignment, drum slipping, or even belt deformation and cracking may occur.

To ensure a smooth oven upgrade, our skilled engineering team provides expert support. With fast, cost-effective solutions, we handle the entire transformation process and eliminate the risks caused by insufficient technical know-how.

After Sales Service

Our experienced after-sales service team can provide you with the following professional steel belt services:

- steel belt welding and installation;

- steel belt interpolation welding;

- steel belt crack repairing;

- adhesive V-rope bunding;

- steel belt dredging;

- mirror belt repairing;

- steel belt cleaning;

- spare parts changing;

- wire-mesh oven upgrading;

- deformed belt repairing.

Seamless Welding Technology

Carbon steel belt welding process is a strong professional technology, which requires professional technicians and installation tools to complete. Good welding quality can greatly improve the stability and service life of steel belt. We have senior engineers with more than 10 years experience can meet almost all kinds of requirements of welding requirements.