NICKEL PLATING CHEMICALS

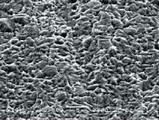

Nickel coatings are used in industry for corrosion protection of steel and non-ferrous metals to improve the wear resistance of surfaces exposed to friction. Nickel plating are cathode toward iron and can provide protection only if no pore therein. Therefore, the steel is first coated with a layer of copper (25-35 mm), and then nickel (10 - 15 mkm). Sulfate-chloride electrolytes are the most widely used. Among electrolytes with additives derived from butynediol fine-grained, supple, smooth brighting coatings are deposited. The main disadvantage of the coating - a small resistance to corrosion caused by sulfur inclusions. This can be avoided by applying two- or three-layer coatings. Increased resistance differ composite nickel coatings containing fine particles of dielectric - kaolin, carbides and others.

Main component of chemical agent for nickel plating is nickel sulphate, that is a crystalline substance of emerald green or turquoise color, water-soluble, ventilating in air. This is one of the types of nickel salts. Nickel sulfate is a highly toxic substance, so when you work with it you must follow the rules for handling hazardous substances. Chemical formula: NiSO4•7H2O.

| The use of nickel sulfate (nickel sulfate heptahydrate, nickel sulphate). Today, nickel sulfate is in demand. In most cases it is used for nickel electroplating of products and metals. It is also used for the manufacture of batteries, catalysts, ferrites, in electronic and electrical industries, in metallurgy and for making alloys. Nickel is widely used in perfumery, fat and chemical industry as a reagent. |

Chemicals for sulfate nickel plating BN1-301

Chemical composition: Nickel sulfate: 250-300 g / l Nickel plating is carried out at temperature of 50-65 ℃ cathode current density 1-8A / dm2 2 and pH of 3.8-4.5. Adjustment of the solution: | Specification: sulphate electrolytes have high electric conductivity, good dispersibility, good brightening properties, are applied for nickel plating of component parts on the suspension and in galvanic drums. |

Chemicals for sulfate nickel plating RNI-5 series

(for electrodeposition in galvanic drums)

Chemical composition: Nickel sulfate: 180-250 g / l Nickel plating is carried out at temperature of 50-65 ℃ cathodic current density 0.1-1.0A / dm ² and pH of 4.0-4.8 Adjustment of the solution: | Specification: the coating is bright, white, soft,it protects well the metal from corrosion. To maintain the composition of the electrolyte at the desired range it is added with buffer compounds, boric acid is most used. Electrolyte is ideal for electrodeposition in galvanic drums. |

Chemicals for glossy nickel plating HB86 series

Chemical composition: Nickel sulfate: 180-250 g / l Adjustment of the solution: | Specification: the coating is uniform, brightening, light, ideal for nickel steel pipes, parts of furniture accessories and as decorative coating luminaires parts intended for illumination of public and residential buildings. Reduction of pitting (appearing of leakage spots on the surface) is caused by the introduction of tension reducers and wetting agents to the electrolyte. |

Chemicals for decorative nickel plating M100 series

Chemical composition: Nickel sulfate: 250-300 g / l Nickel plating is carried out at temperature of 50-65 ℃ in cathodic current density 0.1-2.0A / dm ² and pH: 3.8-4.5 Adjustment of the solution: | Specification: white, bright, soft, decorative coating. The electrolyte does not spoil the appearance of the bath, it has excellent dispersion qualities, suitable for processing of component parts on the suspension and in galvanic drums. |

Chemical agent for matt nickel plating HNI10 series

Chemical composition: Nickel sulfate: 260-320 g / l Nickel plating is carried out at temperature of 50-65 ℃ in cathodic current density: 2-6A / dm ² and pH: 3.8-4.5 Adjustment of the solution: | Specification: is used for matt plating. The coating is highly resistant to corrosion, does not spoil the appearance of the baths. Electrolyte consumption is low. |

Chemical agent for brightening nickel plating SA Series

Chemical composition: Nickel sulfate: 480-550 g / l Nickel plating is carried out at temperature of 50-55 ℃ at cathode current density 0.5-6A / dm ², pH: 4.2-4.8, and voltage of 10-15V rotational speed of 6-10 revolutions / min. Adjustment of the solution: | Specification: bright nickel plating is achieved by the introduction of brighteners to the electrolyte, is used for a uniform coating of bright white pearl color. |

Chemicals for nickel- phosphorus plating MT-877 Series

Chemical composition: Additive MT-877A: 60 ml / l Note: | Specification: coating contains no toxic heavy metals, is environmentally friendly, the phosphorus content is 8-10%. The possibility of using the electrolyte for 10-12 production cycles. High production efficiency, the deposition rate of nickel can be up to 18-23 μm / hour. Coating is bright, brilliant, has high anti-corrosion properties. |

Chemicals for bright nickel- phosphorus plating MT-878 Series

Chemical composition: Additive MT-878A: 60 ml / l Note: | Specification: coating contains no toxic heavy metals, is environmentally friendly, the phosphorus content is 10-12%. The possibility of using the electrolyte for 10-12 production cycles. High production efficiency, the deposition rate of nickel can be up to 18-23 μm / hour. Coating is bright, brilliant, has high anti-corrosion properties. Easy to operate, prepare the electrolyte. |

Additives for improving the depth of nickel plating DS-605

Chemical composition: Additive: 1-2 mL / L Specification: Ideal for filling deep pores in the surface of products. Compatible with any kind of brighteners. |

|

Additive for removing impurities from nickel electrolyte MR-66

Specification: Nickel plating is very sensitive to impurities that enter into the solution from the surface of parts or by anodic solubility. When steel parts nickel plating the solution becomes clogged with impurities of iron, and cooper impurities when plated with copper-based alloys. Removal of impurities is performed by adding special additives to the electrolyte.Additives are simple in operation, can greatly improve baths dispersion. | Chemical composition: Chemical composition |

Additive for removing impurities from brightening nickel electrolyte MR-60

Chemical composition: Additive: 1-2 mL / L. | Specification: widely used to remove copper and zinc impurities from nickel solutions. It prevents the appearing of spots on the surface of products. |

Additive for removing iron from nickel electrolyte MR-607

Chemical composition: Additive: 1-5 mL / L. | Specification: Widely used for removal of iron impurities from nickel solutions. The active additive can be added during the process of bright, semi-bright nickel plating without the need to stop the equipment. |

Addition for removing copper from nickel electrolyte MR-608

Chemical composition: Additive: 1-10 ml / l | Specification: widely used to remove copper impurities from nickel solutions. The active additive can be added during the process of bright, semi-bright nickel plating without the need to stop the equipment. |